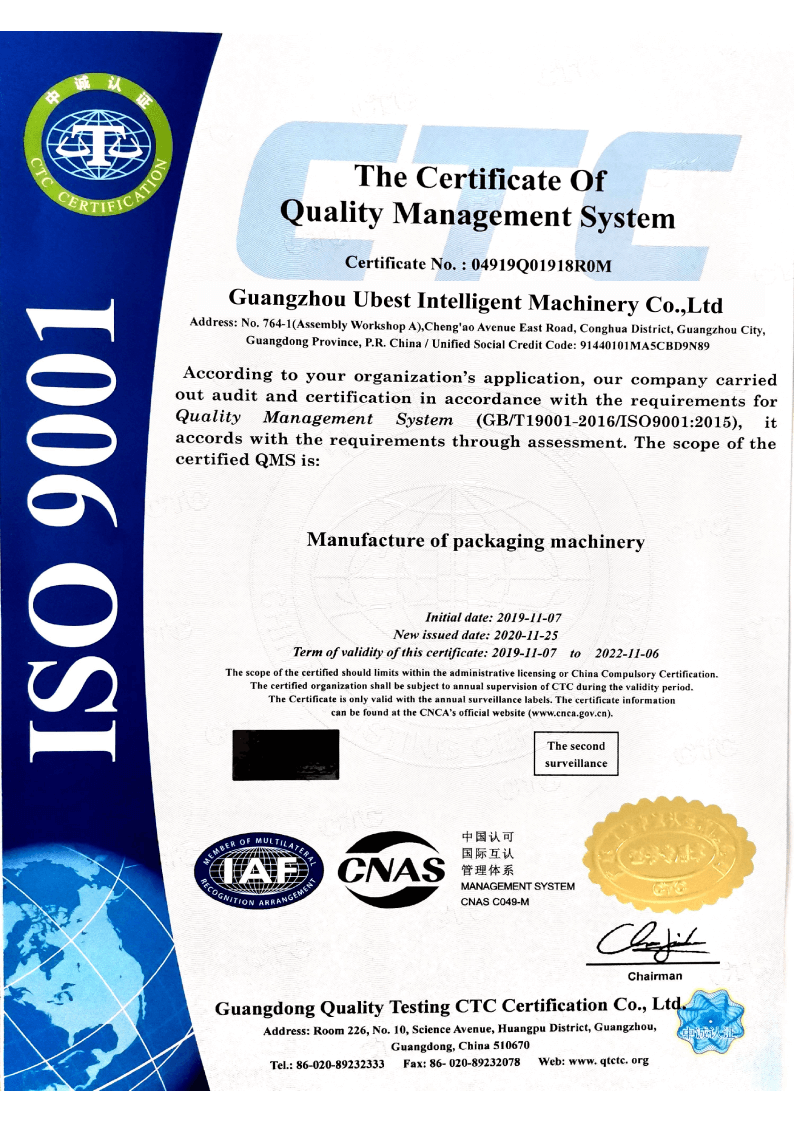

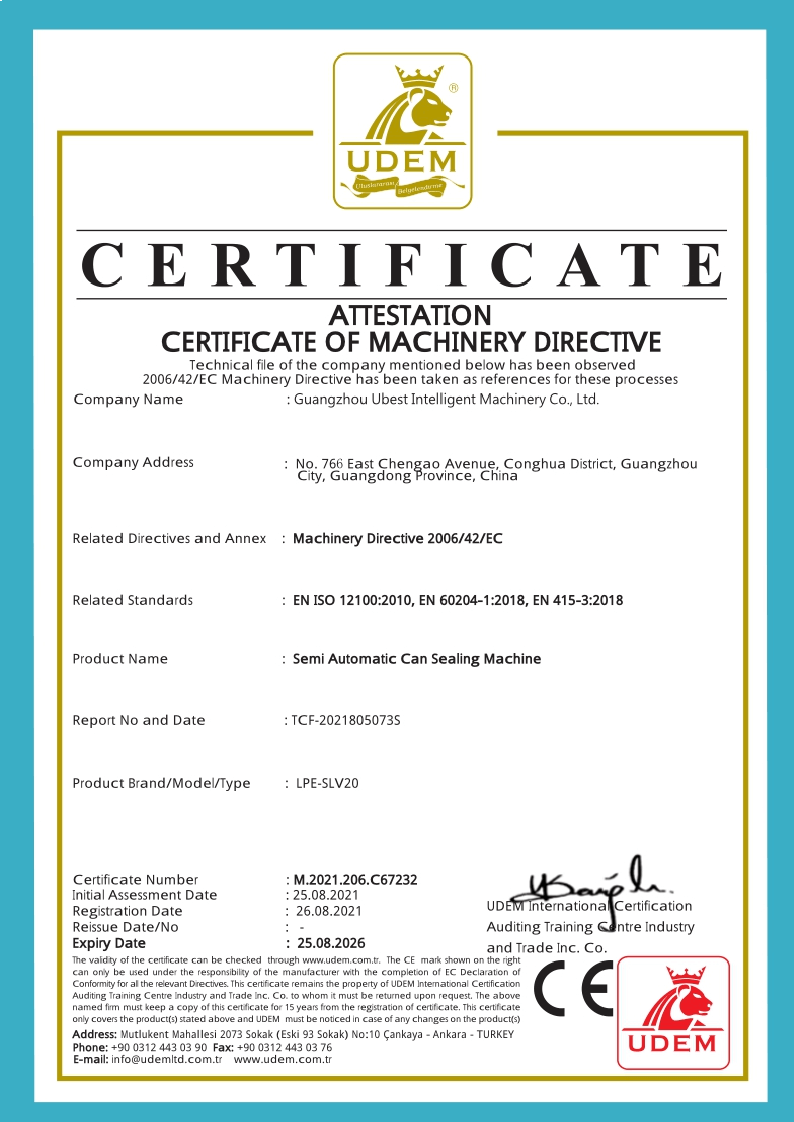

Guangzhou Ubest Intelligent Machinery Co., Ltd. is a China-based manufacturer specialized in production and sale of various of can sealing machines.

Our factory located in Guangzhou City, China, which boasts an area of 2500 m². We have a professional team with 16 years of Research & Development and manufacturing experience in can seamer machines.

Our can seaming machines are controlled by servo motor which is more safety and more convenience. We believe that the future trends of the can seamer machines are becoming simpler & smarter.

At Ubest, our engineers are working on it. We are striving for developing can sealer machines with simple design, a high degree of automation, and lower maintenance. We hope that you can really free your hands & streamline your can packaging production using Ubest can seaming machines.

Our sales network radiates all over the country and is exported to more than 36 countries and regions around the world. With the spirits of“Courage for innovation, free development and constant forging ahead”,the service concept of "taking the customer's needs first", Guangzhou Ubest aims to build a world-renowned can seamer machines.

Ubest has an experienced team for R&D and is able to support OEM & ODM orders. Consult with our expert team to determine which can sealing machine is best for your market.

100 percent in-house manufacture and testing before shipment

We know even the slightest issue of the machine will affect your productivity. So we try our best to ensure the quickest response to any customer questions & requests.

Regular care helps to sustain the quality of the can sealing machine.

To make your machines look polished, at Ubest, we give every can seamer machine a thorough care before delivery including:

> Clean the machine to make it free of debris, stains & hand prints

> Polish with anti-rust oil to prolong its lifetime

The quality of the can sealing machine largely depends on the assembly process.

Just like the assembly of a Swiss watch, the artisan is also the key for machine assembly. Our professionals with years of experience will spend much of their time putting every part into the right place.

Once the assembly is finished, every can seamer machine will go through a careful inspection to ensure:

> All components from lid feeder, conveyor, pneumatic mechanism, sensor to mechanical parts run smoothly

> Electrical parts are correctly installed

> Electrical wiring is eye-pleasing without being loose

> The motor runs without being overheated & noisy

Every part counts for the quality of our can sealing machine.

For making precise parts of can seamer machines, we use sophisticated CNC machines including milling machines, lathes, grinders.

Once all parts for our can seaming machines are ready, an elaborative inspection will be carried out. Our engineers will use professional equipment to make sure the tolerance dimension is within 2um.

Raw materials decide the overall quality of the machine.

At Ubest, we have been partnering with world-renowned brands for the best materials. We guarantee the performance & lifetime of our machines by sourcing:

> Premium #304 or #316 stainless steel

> PLC from Delta/ Mitsubishi/Siemens; Touch Screen from DELTA; Pneumatic component from AIRTAC ; Photoelectric sensor from Autonics; Relay from IDEC; Breaker from Schneider etc.

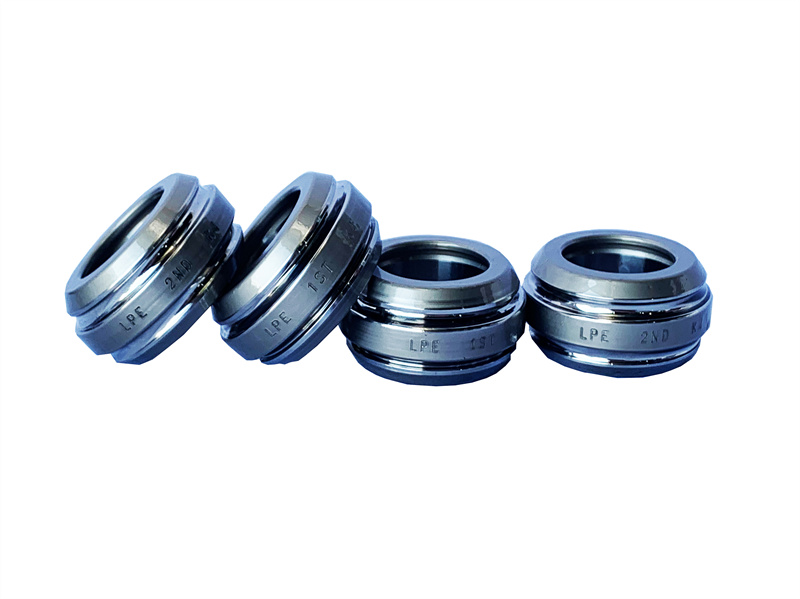

> The roller is imported from Taiwan. The material of can seaming roller is made of SKD Japanese special mold steel, which has a life span of more than 5 million seals each side.

> The material of turntable is made of food- grade PE which is safer.

> The lid feeder device is adopted aviation aluminum material, which is durable and non- rusty.

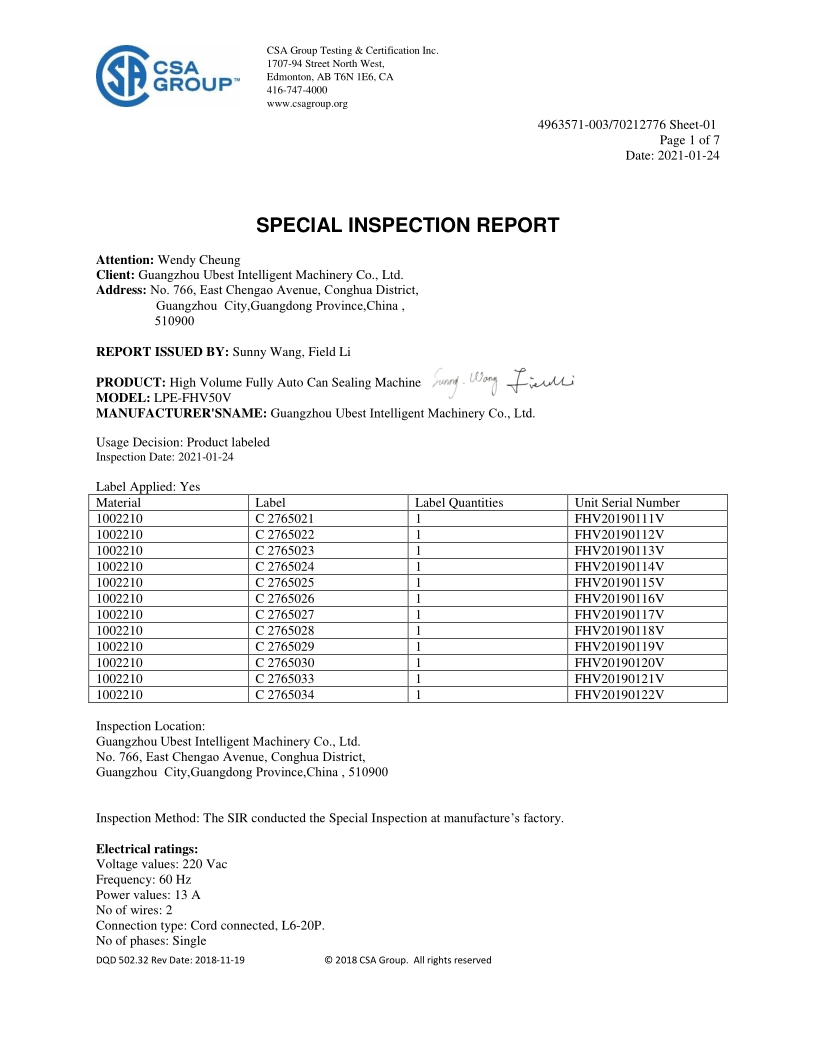

After-production test is as important to guarantee the quality of final product.

Once the machine is ready. our engineer will run a trial test with your sample cans for more than 100 consecutive operations.

After that, a no-load run test lasting 48 hours will be carried out to test the overload protection device.

This makes sure the machine stop when running wrong so the quality of electrial parts is not affected.