As we all know, the can sealing machine improves the efficiency of can packaging operations and reduces production costs, which is why it is widely used in various fields to allow enterprises to generate higher profits. However, you need to know how to use a can sealing machine so that you can make the most of it!

Sealing Process

Cans are sealed by joining the lid to the can body and form a double seam. The outer end of the lid is called the curl, and the outer top portion of the can body is called the flange. The double seam is formed by interlocking the curl of the lid with the flange of the body. Compared to the semi automatic can seaming machine, the automatic can double seaming machine minimizes the degree of manual involvement.

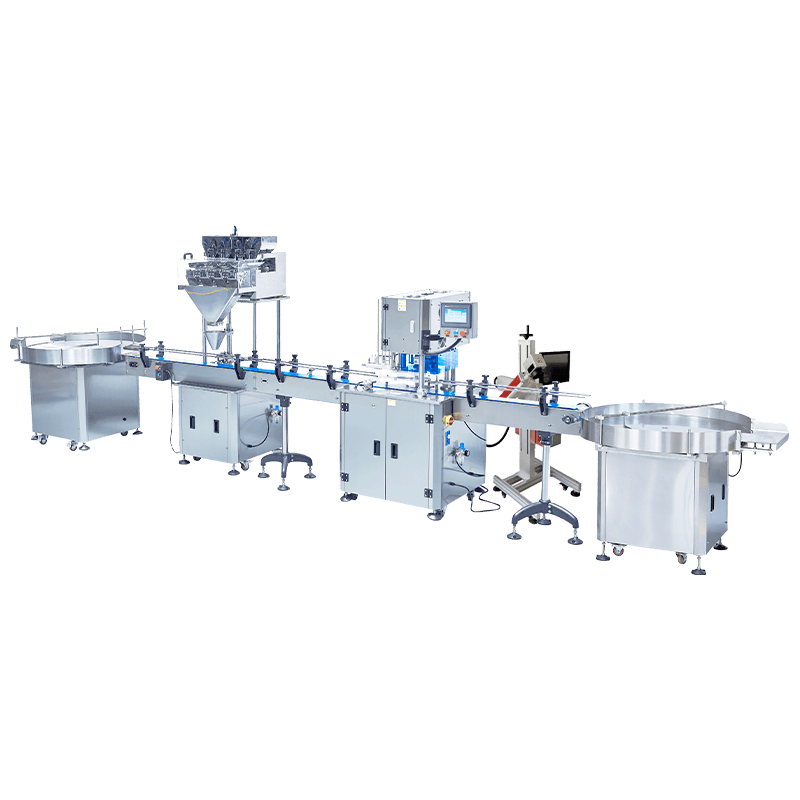

The automatic can sealer machine offers a series of automated processes, your involvement level in the sealing process depends on the type of machine you have. Cans enter the can sealing machine via a conveyor belt, which compresses the curl and flange and mechanically interlocks them together. The can double seaming machine also uses a sealing compound to fill out any remaining gaps, making the double seam airtight.

Set Up The Automatic Can Sealer Machine

Professional can seaming machine manufacturers will provide technical support when you invest in a can sealing machine. The automatic can sealer machine is usually integrated with a production line for a continuous packaging process. Therefore, the operator only needs to start the machine through the control panel and supply it with a large number of lids into the machine and then let it do the rest of the work. But it doesn't mean you don't need to fully understand the operation of the auto can double seaming machine.

Fully Automatic Can Sealer Machine

You need to check out the following items after installing the can sealing machine:

- * All components are running smoothly

- * Electrical components are properly connected

- * Tools are properly installed

- * The wiring is not loose and looks neat

- * The motor is not overheating and making too much noise when running

- * Take a trial run test with your sample to ensure a smooth operation and produce the desired end product.

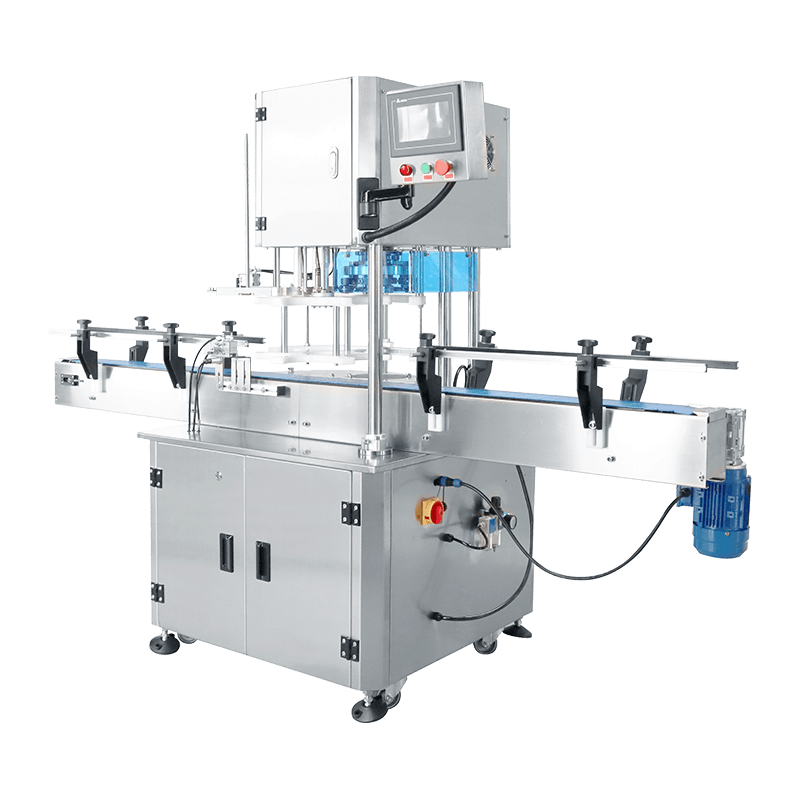

Precautions For Semi Automatic Can Seaming Machine

Adjust the machine components to match the size of the can for proper seaming – the positioning parts can be adjusted to fit different sizes.

Semi Automatic Can Seaming Machine

Check the instructions for the semi automatic can seaming machine to see if it can handle the type of product you want to seal. Some are only suitable for dry products and not for wet foods.

If sealing the cans with dry goods, to prevent the remaining oxygen in the cans from spoiling the product, you can put an absorbing packet in the container before sealing. Please take care when filling the containers, leaving a little space from the edge of each can.

Conclusion

Learning how to use the can double seaming machine is important, helping to make the can sealing operations more efficient. Likewise, choosing reliable can seaming machine manufacturers is also very vital. Ubest is one of the can seaming machine manufacturers and suppliers in China, offering a wide range of high-quality semi automatic can seaming machines and automatic can sealer machines at favorable prices! Please feel free to contact us at info@ubestcanseamer.com for more details!