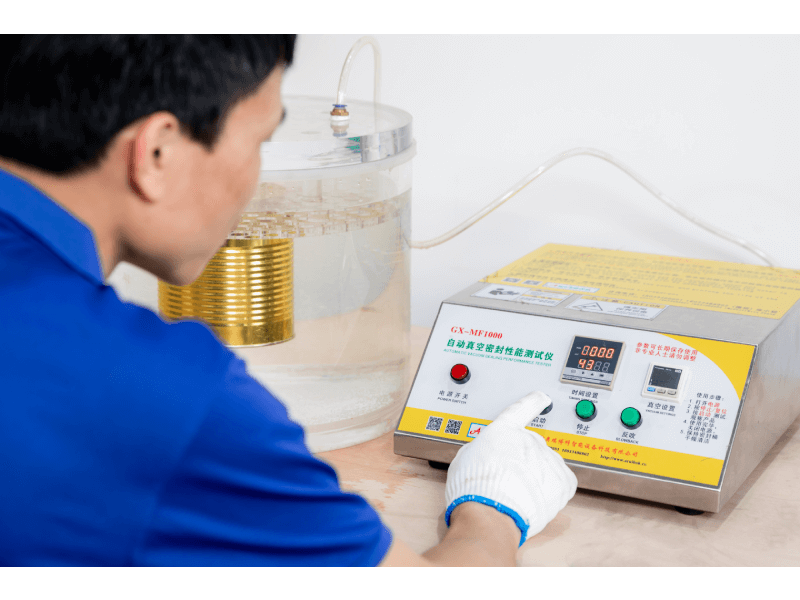

Leakage inspection:

When the sealing is completed, the sealed cans which are picked at random will be put in a vaccum container with the negative pressure -50Kpa.

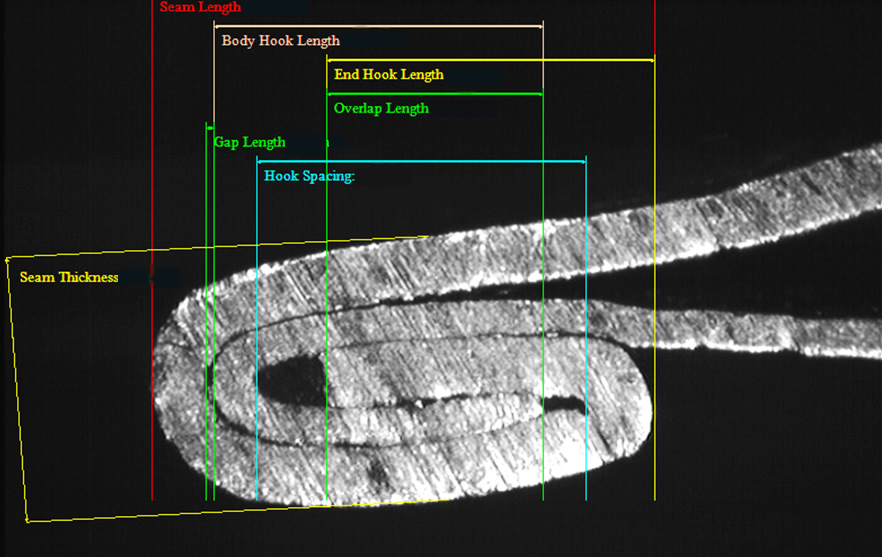

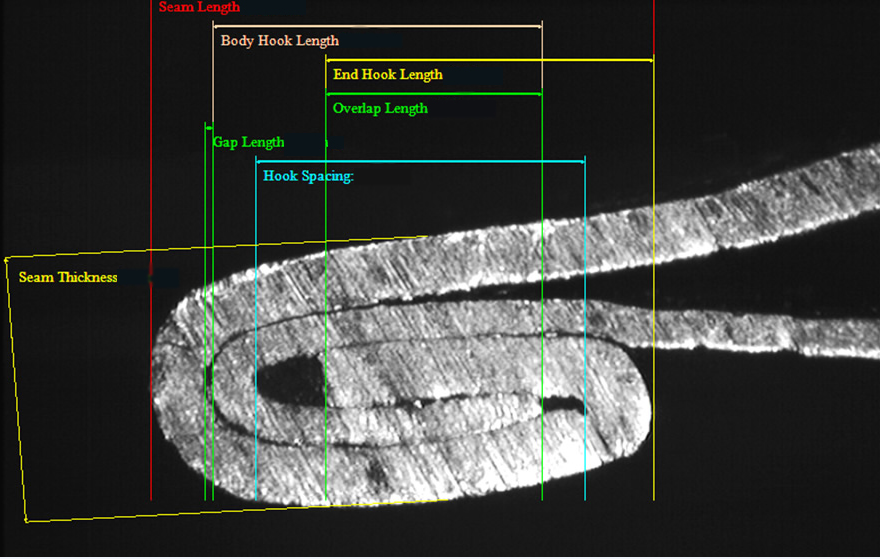

AUTOMATIC SEAM TIGHTNESS MEASUREMENT

Correctly evaluating tightness is critical to maintaining double seam quality. Our factory use VSM-X devicce to measure seam tightness from the captured seam image!

Double seam inspection:

OVERLAP

Calculation of overlap length:

Overlap Length = CH + BH + T – SH

Where CH = Cover Hook

BH = Body Hook

*T = Cover Plate Thickness

SH = Seam Height (Width or Length)

*In general practice, .010″ may be used for the cover thickness. However for accuracy, the actual plate thickness of the cover should be used.

Calculation of percent overlap:

Overlap, % = 100 x (BH + CH + T – SH) / [SH – ((2 x T) + BPT)]

Where BH – Body Hook Length

CH = Cover Hook Length

T = Cover Plate Thickness

SH = Seam Height

BPT = Body Plate Thickness

Use minimum value found for each measurement (maximum value for SH).

PERCENT BODY HOOK BUTTING

Calculation of overlap length:

Body Hook Butting % = A / B x 100

IT IS RECOMMENDED OVERLAP AND BODY HOOK BUTTING BE OPTICALLY MEASURED.