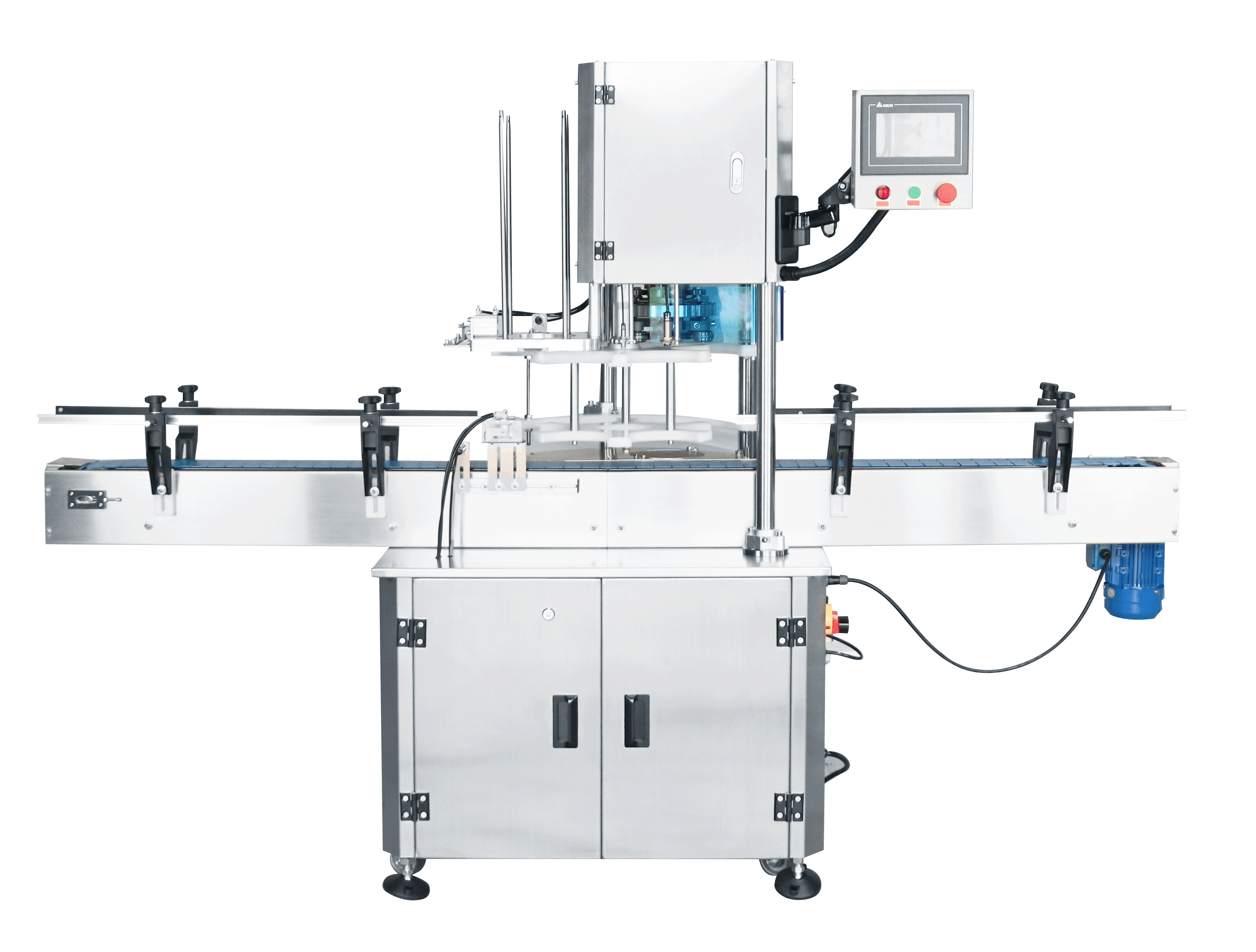

1. Number of sealing head: 1

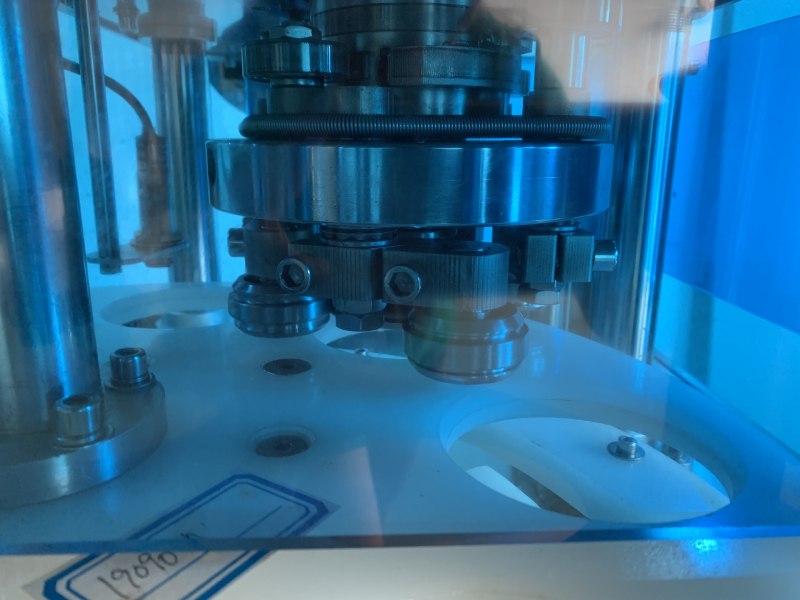

2. Number of seaming rollers: 4 (2 first operation, 2 second operation)

3. Sealing speed: 35 ~ 50 cans / min(adjustable)

4. Sealing height: 25-220mm

5. Sealing can diameter: 35-130mm

6. Working temperature: 0 ~ 45 ° C, working humidity: 35 ~ 85%

7. Working power supply: single-phase AC220V 50/60Hz

8.Air pressure: ≥0.6MPa

8. Total power: 2.1KW

9. Weight: 450KG (about)

10. Dimensions: L245* W 85* H165cm

Features:

Application:

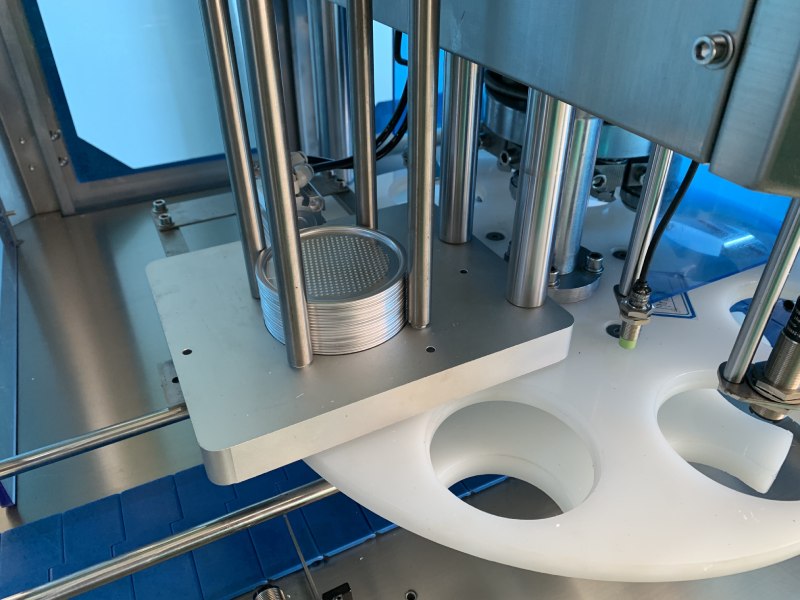

Applicable to tin cans, aluminum cans, plastic cans and paper cans, it is the ideal packaging equipment for food, beverage, Chinese medicine drinks, chemical industry etc.

The conveyor is put on the top of our fully automatic can sealing machine, which can be installed and dismantled easily. Besides, it’s easy to clean and maintain.

The material of our lids-feeder adopts aviation aluminum which cannot be rusty.

It can be put more than 260 lids, and no need to put lids frequently, improving production efficiency.

The turntable only runs when there is a can, and the turntable will automatically stop when there is a can stuck. After one button reset, the error can be released, and the machine restarts to run. When there is a foreign object stuck in the turntable, it will automatically stop running to prevent artificial Equipment damage and safety accidents caused by incorrect operation of the equipment.

The roller is imported from Taiwan. The material of can seaming roller is made of SKD Japanese special mold steel, which has a life span of more than 5 million seals each side.

Adopting four seaming rollers from Taiwan, they are used for symmetrical installation. Two of them complete the hem, and the other two complete the crimping. The principle is simple, the adjustment is convenient, and the force is balanced.

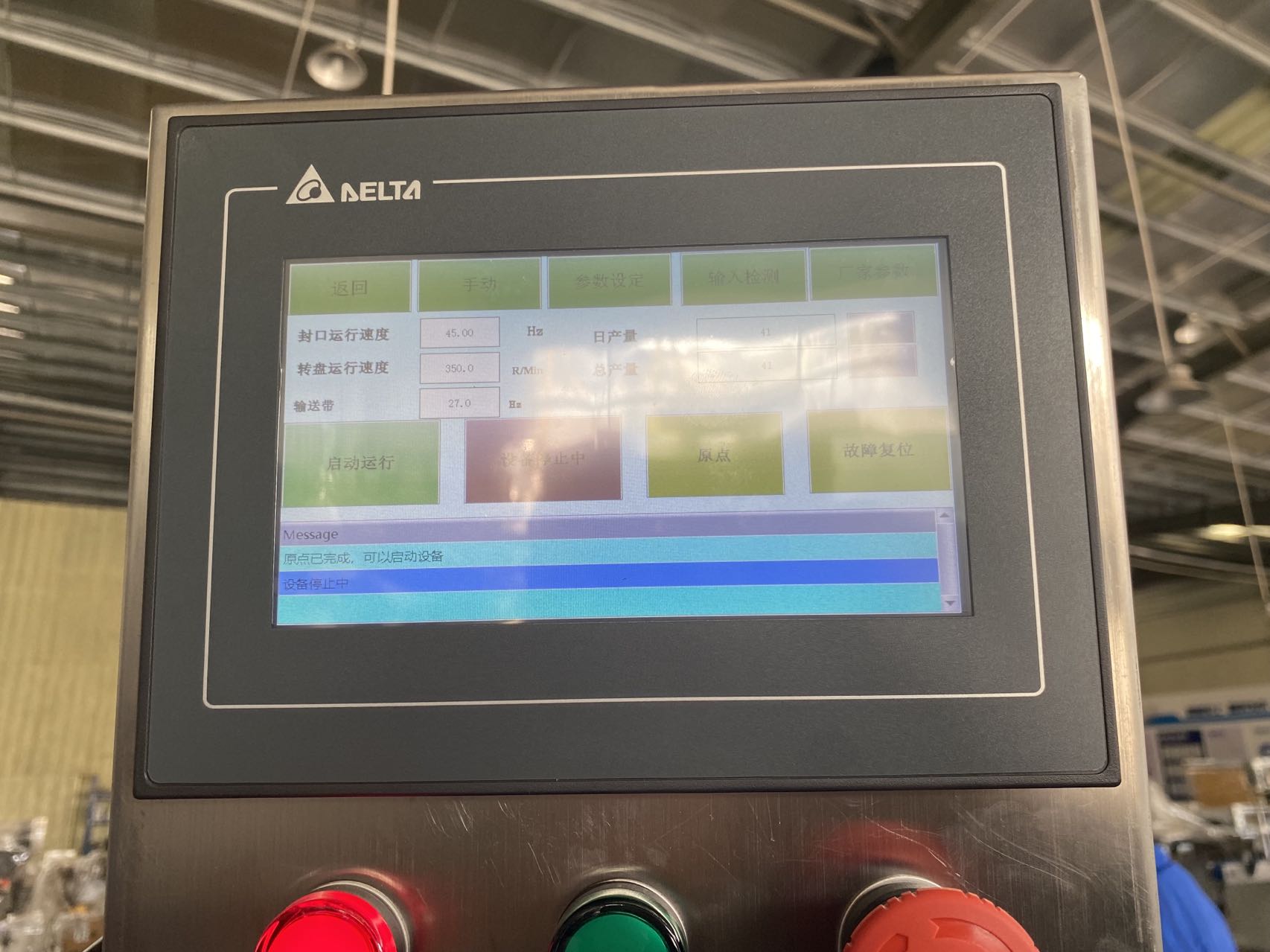

Imported PLC cooperates with touch screen man-machine interface, making the machine runs stable and easy to operate.

The touch screen is connected by a bracket, which can be operated in multiple directions, and is more flexible during operation.

The sealing speed can reach up to 60 cans per minute and is adjustable(about 25-60 cans per min). It depends on the products and can sizes.

The machine has a transparent acrylic cover, multiple protection, more beautiful and safe.