1. Number of sealing head : 1

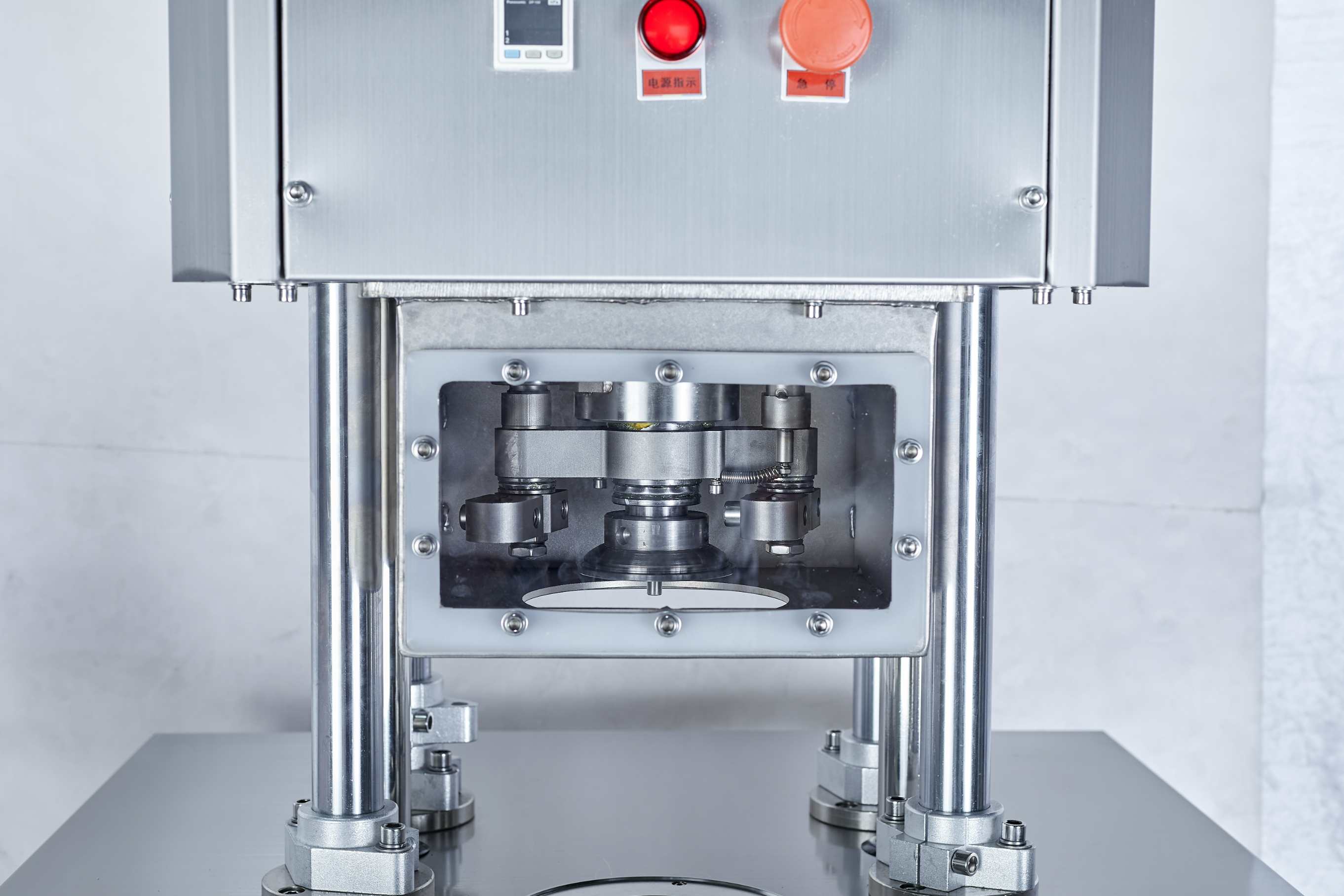

2. Number of seaming roller: 2 (1 first operation, 1 second operation)

3. Sealing speed:3-4 cans / min (related to the can size)

4. Sealing height: 25-220mm

5. Sealing diameter: 35-130mm

6. Working temperature: 0 ~ 45 ° C, working humidity: 35 ~ 85%

7. Working power supply: single phase AC220V 50/60Hz

8. Total power: 2KW

9. Weight: 365KG (about)

10. Dimensions:L 85* W 85* H 145cm

11. Working pressure (compressed air) :0.5-0.6MPa

12. Air consumption (compressed air): about 60L/min

13. Nitrogen source pressure ≥0.2MPa

14. Nitrogen consumption: about 50L/min

15. Minimum vacuum pressure -0.07MPa

16. Residual oxygen content <3%

1.This equipment is suitable for all kinds of round tinplate cans, plastic cans. First vacuum then nitrogen, and finally sealed. Effectively extend the product shelf life, ideal for food, beverage, pharmaceutical and other industries.

2. It adopts the working mode of single chamber.

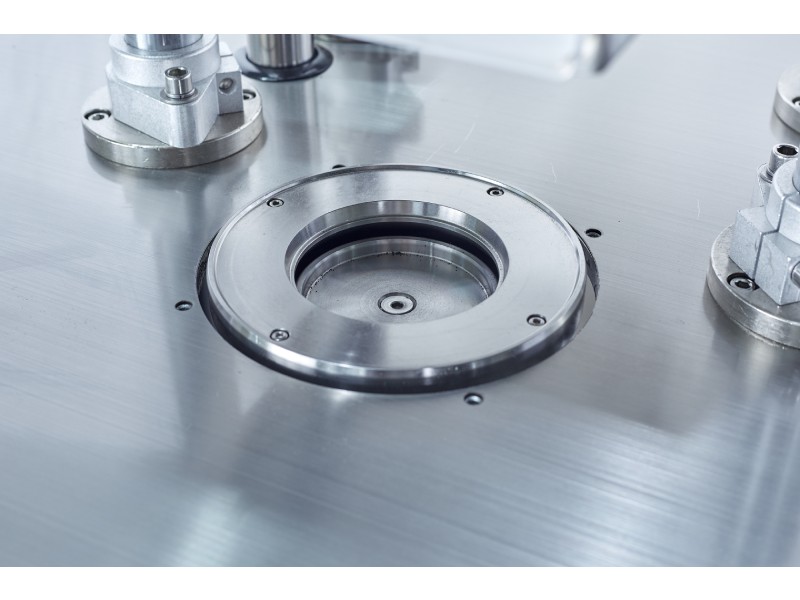

3. The seaming rollers and chuck are processed by Cr12 die steel, which is durable and high tightness.

4. The residual oxygen content is less than 3%, effectively extending the shelf life of the product and improving product quality.

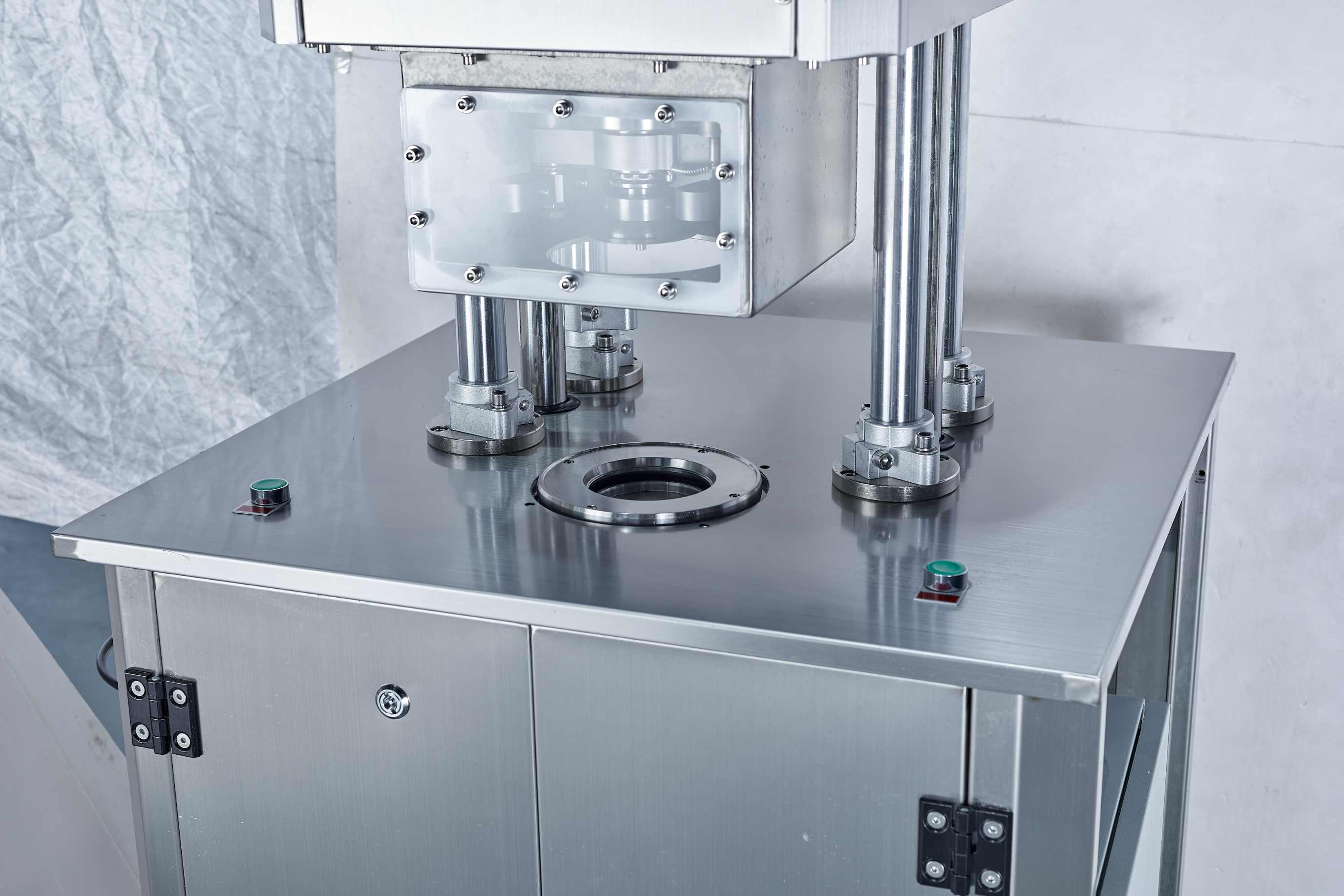

There are two operating buttons to ensure operation safety.

Vacuuming, N2 flushing, sealing are finished at the same one chamber to ensure good working performance.

.jpg)

The seaming rollers and chuck are processed by Cr12 die steel, which is durable and has high tightness.

Extremely low vacuum degrees can be achieved with a high-pressure vacuum pump.

The residual oxygen content is less than 3%, effectively extending the shelf life of the product and improving product quality.