Packaging has come a long way, from its rudimentary forms to the sophisticated systems we see today. Among the crucial elements of modern packaging is the sealing process, which ensures product integrity, longevity, and freshness. With the rapid advancements in technology, the emergence of electric tin can sealer machines has revolutionized the packaging industry, offering unparalleled efficiency and precision.

Understanding Electric Tin Can Sealer Machines

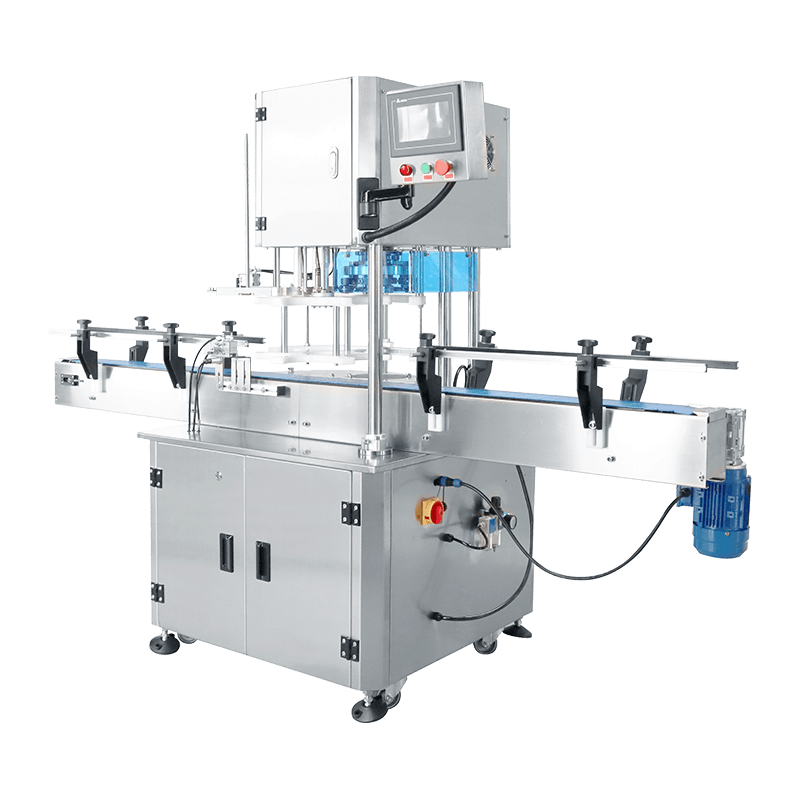

Electric tin can sealer machines represent the epitome of packaging innovation, embodying intricate components working in harmonious synergy. The sealing process itself is a fusion of pressure and heat to fuse the can and its lid seamlessly.

At its heart lies the electric motor unit, an engineering masterpiece that orchestrates the entire mechanism with unparalleled accuracy. And the control panel, a central command hub, allows operators to regulate and monitor the sealing process with utmost accuracy.

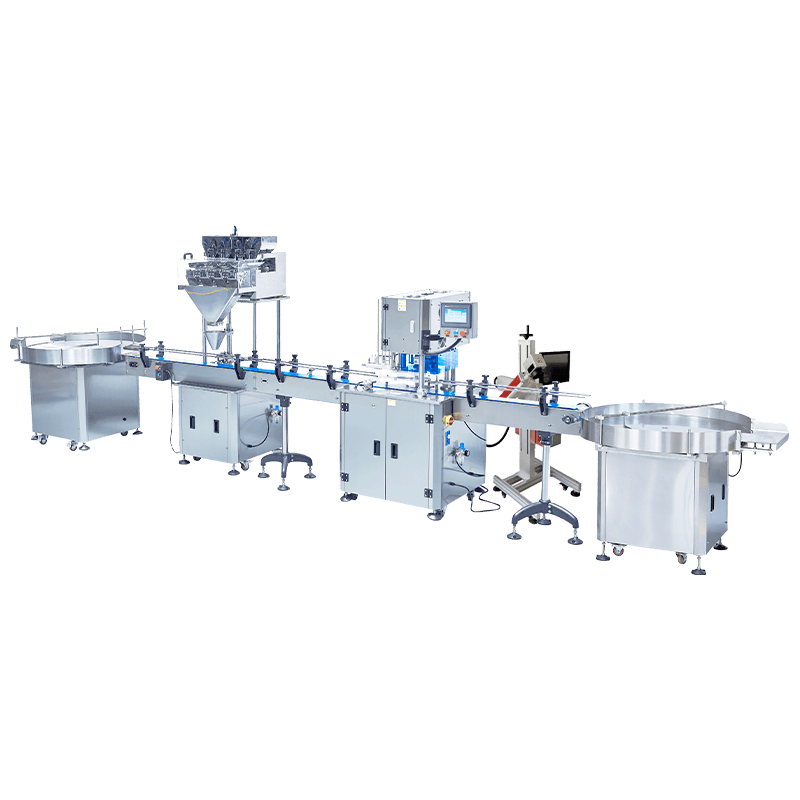

electric tin can sealer machine

These versatile machines cater to a wide array of can types and sizes, making them indispensable across various industries.

- In the food and beverage sector, electric tin can sealer machines ensure that products stay uncontaminated and fresh, extending shelf life and retaining flavors.

- Industries dealing with chemicals and industrial products rely on these machines to provide a secure seal, preventing leakage and ensuring safe transportation.

- The pharmaceutical sector benefits from these machines to maintain a sterile environment, safeguarding the potency of medical products.

Benefits of Electric Tin Can Sealer Machines

The merits intrinsic to electric tin can sealer machines are both transformative and far-reaching. A notable highlight is the airtight sealing precision they provide. The sealing process is executed with meticulous accuracy, leaving no room for air or contaminants to infiltrate the can. This hermetic seal contributes significantly to the preservation of products, resulting in an extended shelf life and minimized wastage.

Furthermore, electric tin can sealer machines enhance production efficiency. Their automated nature ensures consistent sealing quality, irrespective of the operator's skill level. This not only streamlines the packaging process but also reduces human error, optimizing overall productivity. Additionally, the hygiene and contamination control these machines offer is unparalleled. The sealing process takes place in a controlled environment, minimizing the risk of external contaminants compromising the product's quality and safety.

Constant speed can sealing machine

Selecting the Right Electric Tin Can Sealer Machine

Choosing the appropriate electric tin can sealer machine is a critical decision that entails careful consideration.

Firstly, the types and sizes of cans to be sealed must be taken into account. Different industries have varying can specifications, and the machine chosen should cater to these requirements seamlessly.

Second, automation and customization options are also crucial factors. Depending on the production process, a fully automated or semi-automated electric tin can sealer machine might be more suitable. Customization allows tailoring the sealing process to specific needs, further optimizing efficiency.

Then, production volume and speed requirements must not be overlooked. High-volume industries necessitate machines with swift sealing capabilities to keep up with demand. Conversely, smaller-scale operations might prioritize precision over speed.

Lastly, maintenance and technical support play a pivotal role in the machine's lifespan. Ensuring that the manufacturer provides reliable support and maintenance services is essential to mitigate downtime and disruptions.

Conclusion

The advent of electric tin can sealer machines has redefined packaging dynamics across industries. From their intricate components to the advantages they offer, these machines have proven to be invaluable assets.

As the realms of technology surge forward, electric tin can sealer machines are poised to exert an even more pronounced influence in shaping the packaging landscape. Please feel free to contact us at info@ubestcanseamer.com for further information!