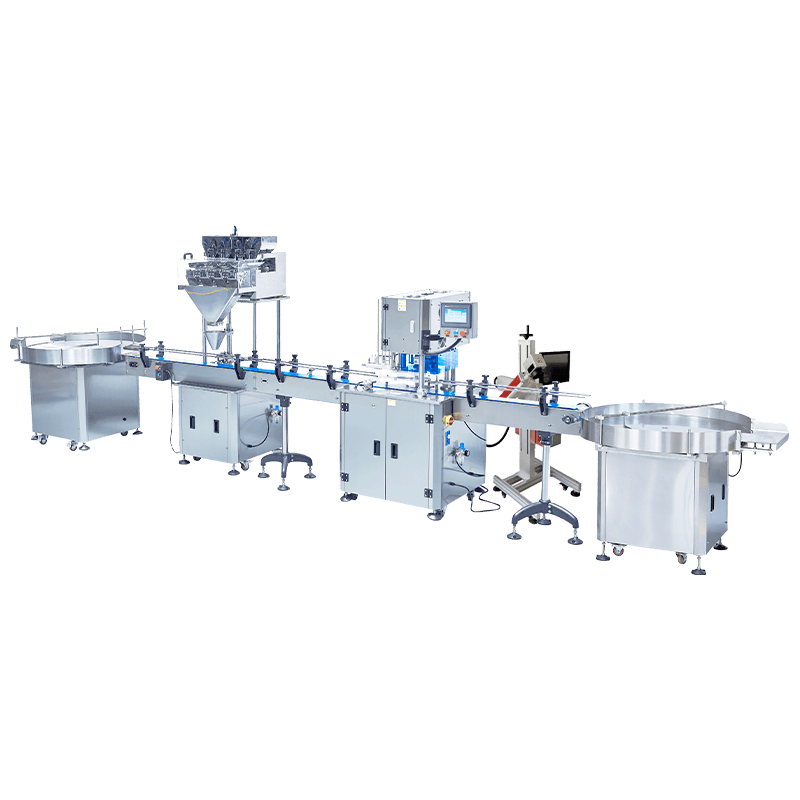

Semi automatic can seamers have emerged as pivotal tools within the packaging industry, adeptly transforming the seemingly mundane act of sealing cans into a precise and efficient process. As the demand for canned products continues to surge, understanding the inner workings and benefits of these innovative machines becomes increasingly imperative.

Definition and Functionality

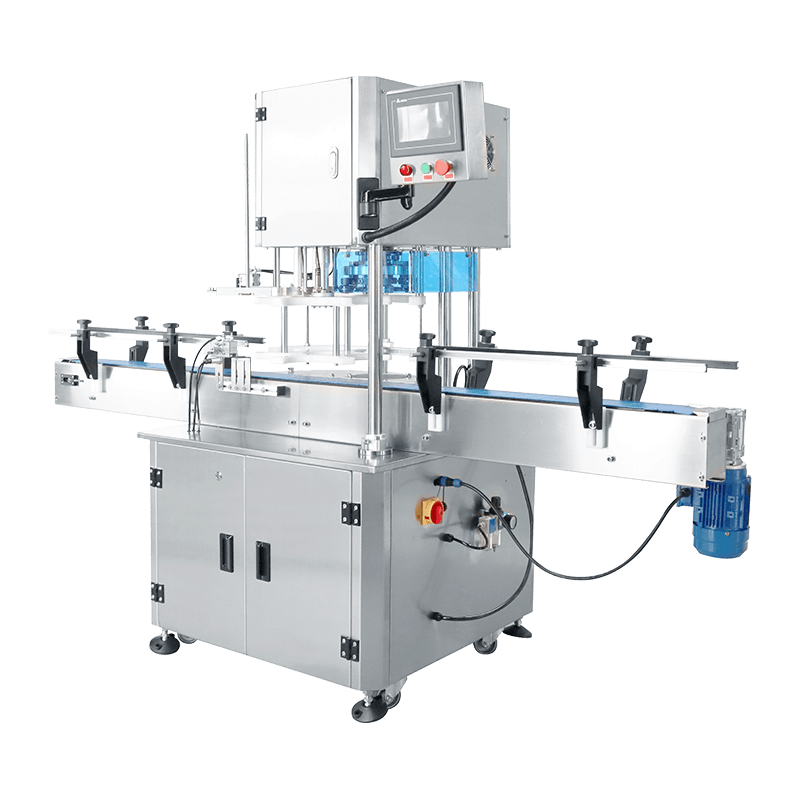

The semi automatic can seamer is a mechanical device that automates the can sealing process while retaining a degree of human intervention. This hybrid nature allows for a delicate balance between technological precision and human oversight. The can seamer delicately manipulates the can's lid and body, securing them in place and forming a hermetic seal that ensures the contents remain uncontaminated and fresh.

Advantages of Semi Automatic Can Seamers

Precision and Consistency

Semi automatic can seamers shine as paragons of precision, consistently delivering flawless seals that safeguard the integrity of the packaged product. The mechanical precision of these machines ensures that each can undergoes an identical sealing process, virtually eliminating the variability often associated with manual labor. This level of consistency not only enhances product quality but also minimizes the risk of leaks and contamination.

Labor Efficiency

One of the standout merits of semi automatic can seamers lies in their ability to optimize labor resources. By automating a substantial portion of the sealing process, these machines alleviate the need for intensive human labor, allowing skilled operators to focus on overseeing and fine-tuning the process. This symbiotic interaction between humans and machine heralds a new era of efficient production, where human expertise complements technological prowess.

Versatility in Can Sizes

Semi automatic can seamers exhibit impressive adaptability to a diverse range of can sizes, accommodating the packaging needs of various industries. Whether sealing petite containers of delicate gourmet treats or larger vessels brimming with industrial components, these machines can be configured to ensure a seamless and secure closure, regardless of the can's dimensions.

Operating Principles of Semi Automatic Can Seamers

Can Placement and Alignment

The commencement of the can sealing process pivots on meticulous can placement and alignment. The can seamer deftly positions the can body and lid in perfect congruence, setting the stage for the subsequent sealing operation. This intricate dance between mechanical precision and geometrical alignment forms the foundation of a successful seam.

Seam Formation Process

The heart of the semi automatic can seamer lies in its seam formation process, a harmonious choreography of rollers, chucks, and seaming heads. As the can and lid are gently pressed together, the seaming heads exert a controlled force, gradually shaping the metal into a secure seam. This intricate ballet culminates in a seam that not only exudes aesthetic finesse but also guarantees an airtight enclosure.

Quality Control Mechanisms

Amidst the rhythmic clattering of machinery, quality control mechanisms function as sentinels, vigilantly monitoring each seam for imperfections. Ultrasonic sensors and optical detectors scrutinize the seam's dimensions and integrity, promptly flagging any deviations from the prescribed parameters. This real-time oversight underscores the commitment to delivering packaging solutions of unparalleled excellence.

Choosing the Right Semi Automatic Can Seamer

Can Size and Production Volume

Selecting the ideal semi automatic can seamer hinges on a strategic evaluation of can size and production volume. Each machine boasts a unique capacity and throughput, making it imperative to match these attributes with the demands of the packaging line. A harmonious synchronization of can dimensions and production volume is a fundamental prerequisite for seamless operations.

Material Compatibility

The compatibility between the can seamer and the materials being used is a cornerstone of efficient and durable packaging. Different metals and alloys react diversely to the seaming process, necessitating a meticulous assessment of material compatibility. A judicious selection in this realm ensures that the packaging process not only preserves the product's integrity but also upholds the machinery's longevity.

Ease of Maintenance

Behind the curtain of seamless packaging lies the necessity of maintenance and upkeep. Opting for a semi automatic can seamer with a user-friendly maintenance regime can greatly alleviate downtime and operational disruptions. Machines equipped with modular components and intuitive diagnostics empower operators to address issues and restore production rhythm swiftly.

Conclusion

The semi automatic can seamer stands as an emblem of innovation, seamlessly merging human ingenuity with mechanical precision. With a keen understanding of its advantages, operating principles, and factors influencing its selection, industries can embark on a journey toward efficient, consistent, and superior can sealing.