In the fast-paced world of food packaging, efficiency, and quality are paramount. The vacuum can seaming machine has emerged as a revolutionary solution to address these concerns, reshaping the packaging industry. With its cutting-edge technology, this machine enhances the sealing process, ensuring hermetic closures that preserve freshness and prevent contamination.

How Does the Vacuum Can Seaming Machine Work?

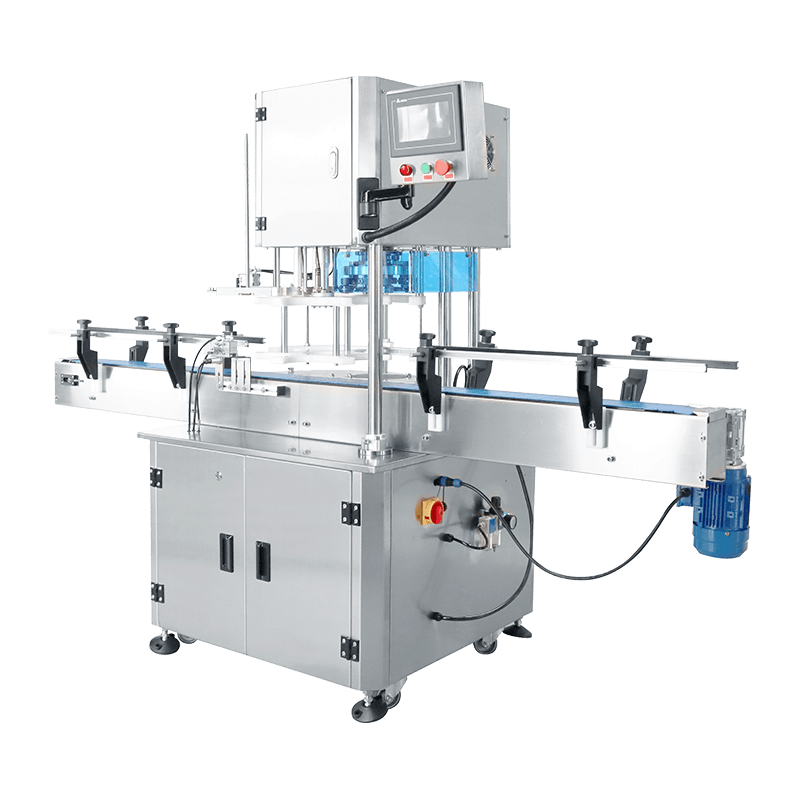

The vacuum can seaming machine operates through a systematic process that ensures airtight seals.

Vacuum Creation: The machine introduces a vacuum within the can, removing excess air and gases. This step minimizes oxygen, which is crucial for preserving the quality of packaged food.

Precise Seaming: The can lid is carefully aligned and sealed using precision seaming mechanisms. This process guarantees consistent, secure closures that prevent leaks and contamination.

Final Inspection: Modern vacuum can seaming machines are equipped with advanced sensors and cameras for quality control. Each sealed can undergoes a final inspection to detect any abnormalities or imperfections.

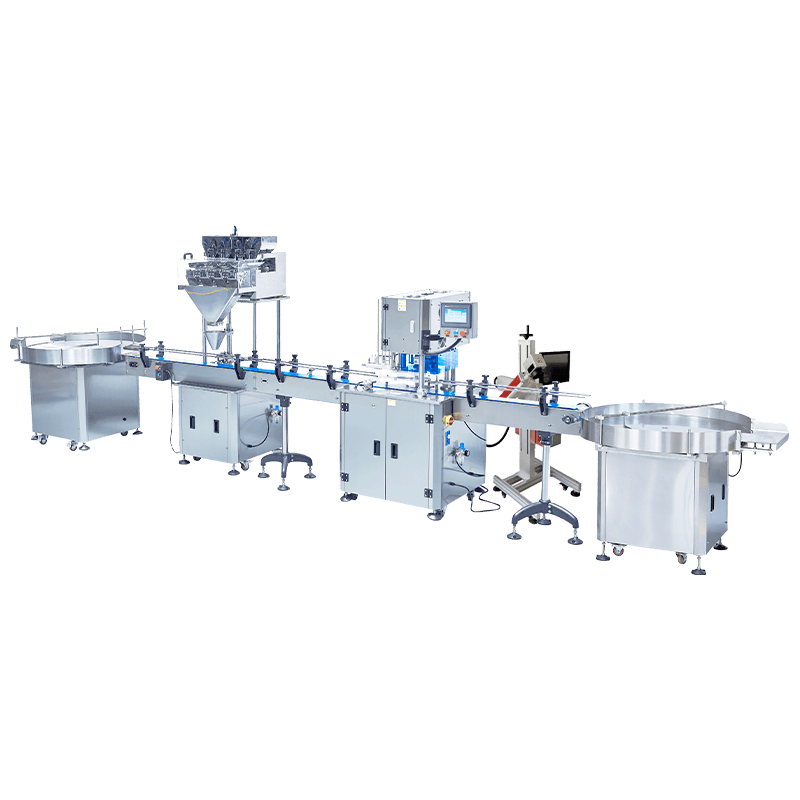

Semi Automatic Double Chambers Vacuum N2 Flushing Can Seaming Machine

Advantages of Vacuum Can Seaming Machine

The vacuum can seaming machine is an advanced piece of equipment designed to streamline and optimize the sealing process of food cans. It employs a combination of vacuum technology and precision seaming mechanisms to create airtight seals that extend shelf life and maintain product quality.

This machine is a game-changer for food manufacturers, offering unparalleled control over the packaging process. The vacuum can seaming machine presents a multitude of advantages that significantly impact the food packaging industry.

Enhanced Freshness

By creating a vacuum within the can before sealing, the machine removes excess air and minimizes oxygen exposure. This preservation technique extends the freshness of packaged food, reducing spoilage and food waste.

Improved Quality Control

The machine's precise seaming mechanism ensures consistent and reliable seals, reducing the risk of leaks or contamination. This level of quality control is essential for maintaining consumer trust.

Increased Efficiency

Automating the sealing process with the vacuum can seaming machine accelerates production rates. Manufacturers can package a larger volume of products in less time, boosting overall efficiency.

Diverse Applications

From canned vegetables to ready-to-eat meals, the vacuum can seaming machine accommodates various food products. Its versatility makes it an ideal choice for a wide range of packaging needs.

Extended Shelf Life

The hermetic seals created by the machine prevent the ingress of external elements, such as moisture and pests, which can compromise product integrity. As a result, the shelf life of packaged goods is significantly prolonged.

Real-World Applications

The vacuum can seaming machine finds application in various sectors of the food industry.

Canned Vegetables: The machine ensures that canned vegetables retain their natural freshness, colors, and flavors, appealing to health-conscious consumers.

Soups and Sauces: Hermetically sealed cans prevent moisture and air from degrading the quality of soups and sauces, maintaining their taste and texture.

Beverages: Carbonated beverages are preserved without loss of fizz, and non-carbonated drinks stay uncontaminated and flavorful.

Pet Food: Just as essential for our furry friends, the machine maintains the nutritional value and palatability of pet food products.

Ready-to-Eat Meals: The vacuum sealer maintains the taste and texture of ready-to-eat meals, making them a convenient choice for consumers.

Conclusion

The vacuum can seaming machine stands as a remarkable innovation in the realm of food packaging. Its ability to create airtight seals through vacuum technology ensures extended shelf life and uncompromised quality.

By automating and optimizing the sealing process, can sealing machine enhances efficiency and allows manufacturers to meet consumer demands effectively. Please feel free to contact us at info@ubestcanseamer.com for further information!