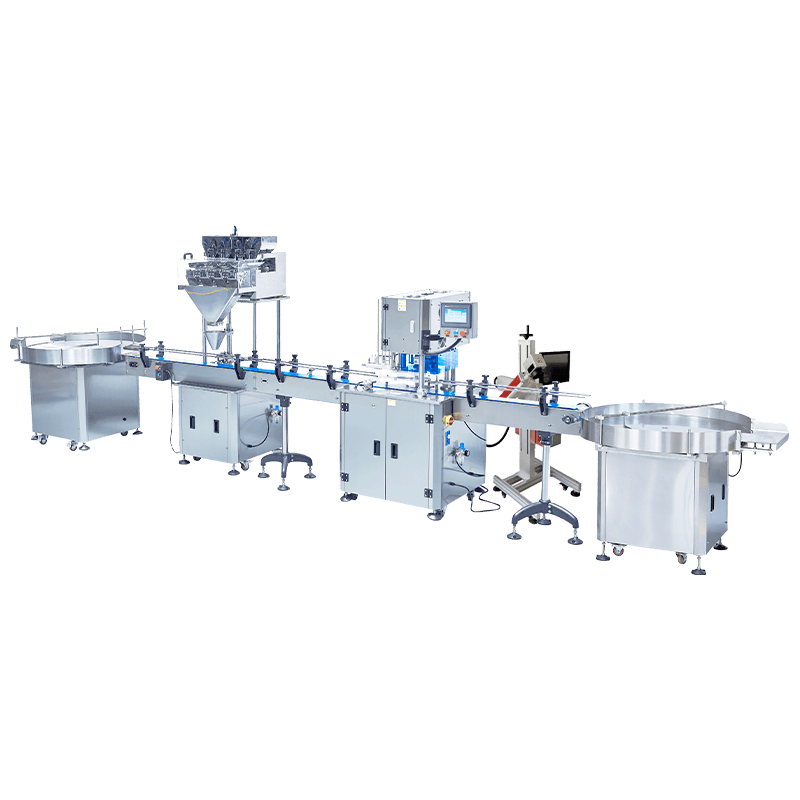

In the food manufacturing industry, can sealing plays a vital role in preserving the flavor, texture, and quality of canned goods. This is where the round can seaming machine comes in. With its ability to seal cans quickly, efficiently and hygienically, manufacturers can maintain a consistent production rate without compromising on quality. In this blog post, we will provide you with an overview of how the round can seaming machine works, its features, and its benefits.

How does a round can seaming machine work?

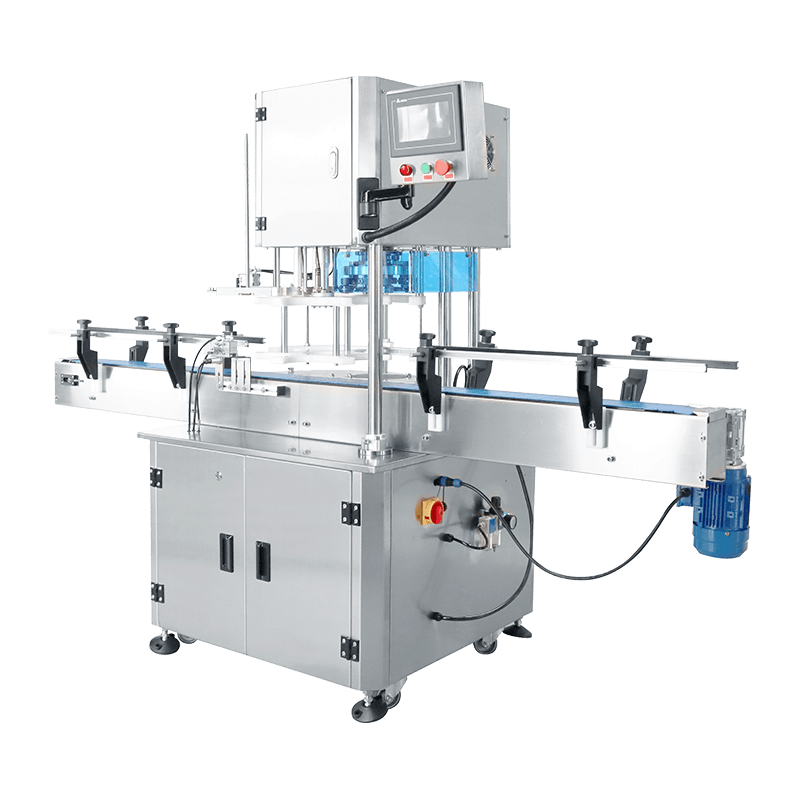

A round can seaming machine is an automated tool that uses rollers and seaming heads to seal the lid onto the can. The can is fed into the machine, and the seaming heads clamp onto the can while the rollers turn the can in a circular motion. The seaming heads guide and fold the metal of the can’s lid and body together, forming a hermetic seal that protects the contents from the environment. The machine performs this operation with high accuracy and speed, ensuring that the seals are consistent and free from wrinkles, leaks, or any other defects.

What are the key features of a round can seaming machine?

The round can seaming machines come with several features that cater to the different needs of the food manufacturing industry. Here are some of the main characteristics to look out for.

Automatic lubrication systems: To provide constant lubrication, prolong the life of the machine, and improve production efficiency.

Multiple seaming heads: To accommodate different can sizes and shapes. Machines usually come equipped with interchangeable seaming heads.

Simple design: To facilitate the ease of use, operation, and maintenance.

High speed: To enable high-volume can sealing with minimal downtime.

Compatibility with different metals: To allow can food manufacturers to choose the most suitable metal for their products.

What are the benefits of using a round can seaming machine?

Consistency: With automated sealing, manufacturers can rely on the same seal quality day in and day out, thus maintaining a high level of quality control.

Efficiency: The machine can process a high volume of cans in a relatively short time. This translates into increased production rates, reduced downtime, and higher profits.

Hygiene: Round can seaming machines are designed to meet strict hygiene standards. The machines are easy to clean and disinfect, and they minimize the risk of cross-contamination.

Versatility: Round can seaming machines can accommodate different sizes and shapes of cans. Manufacturers can experiment with packaging options, offering consumers a wider range of products.

Conclusion

Round can seaming machines are a must-have for can food manufacturers who want to maximize their production output without sacrificing quality, consistency, and hygiene. By investing in a can seaming machine, can food manufacturers can enjoy the many benefits of automated can sealing and improve their competitive edge. It is a wise investment that is sure to pay off in the long run.