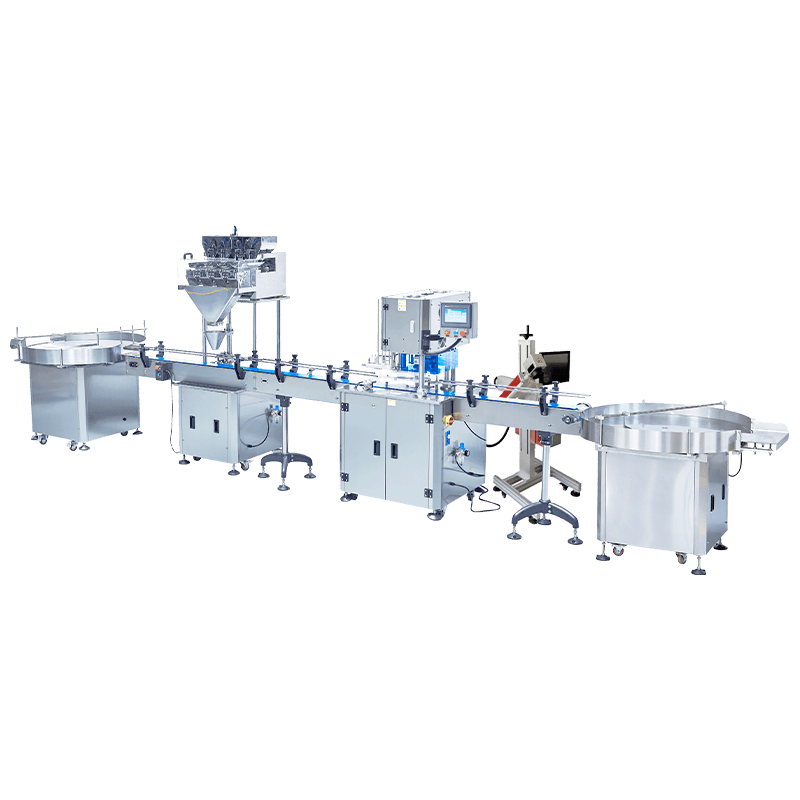

Beverage can manufacturers need to ensure that their products are safe, secure, and of high quality. One crucial aspect of this process is the proper sealing of the can. The capping process, however, can be time-consuming and tedious, especially without automation.

Thankfully, an automated capping machine can significantly improve the overall efficiency of canning lines. This blog post discusses the benefits of investing in an automated capping machine for beverage can manufacturing.

Increased Efficiency

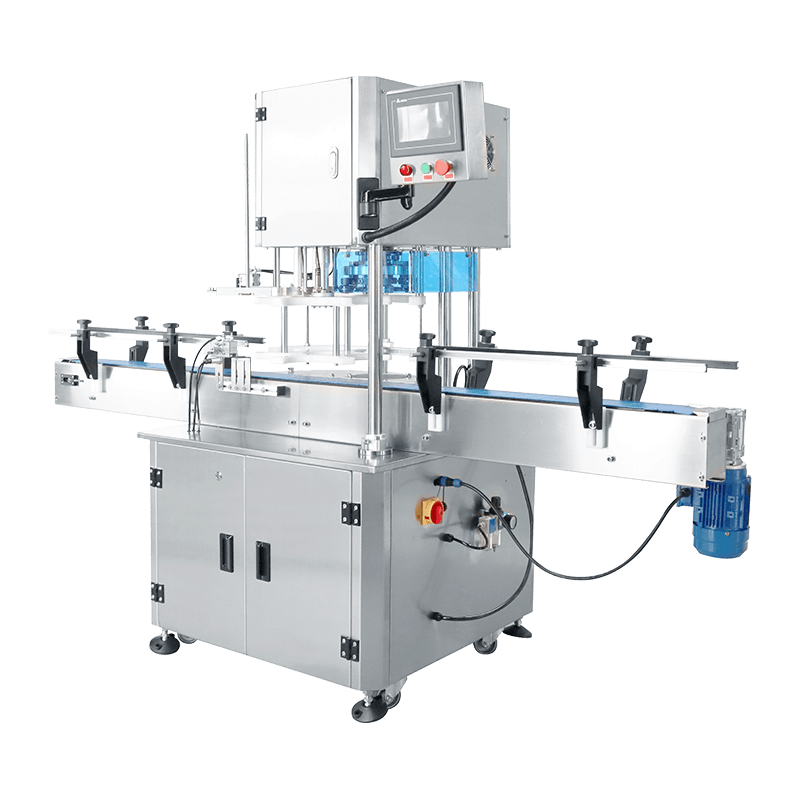

An automated capping machine can cap many cans quickly and accurately. This technology can cap the number of cans per minute from dozens to hundreds or even thousands, depending on the size of the can and the machine’s capabilities. The automation also ensures the caps are correctly aligned, and that the torque applied is consistent. This efficient process frees up personnel to do other tasks, increasing overall line productivity.

Improved Quality

Using an automated capping machine can also improve the overall quality of the capped cans. The machines use a consistent cap-applying process, ensuring that each can have the right amount of torque and cap alignment. Quality control is vital in the beverage industry, and having a consistent capping process ensures that product is not wasted, and customer satisfaction is maintained.

Enhanced Safety

Manually capping cans can be hazardous, as it exposes employees to sharp edges and other hazards. An automated capping machine reduces the risks associated with manual capping, increasing overall safety at the plant. The machine will do the entire process without jeopardizing workers’ safety, giving manufacturers more peace of mind.

Adaptability

An automated capping machine can accommodate various can sizes, types, and cap designs, making it an adaptable piece of equipment. This versatility means that manufacturers can produce different products without worrying about a new capping machine purchase. With food and beverage trends changing, an adaptable capping machine can cater to varying consumer demands.

Savings

Investing in an automated capping machine can be costly upfront, but the savings in the long run can be significant. Automated capping machines are efficient, reliable, and safe. As such, there is a reduced risk of product returns or recalls due to faulty capping. This saves the manufacturer money and helps maintain customer satisfaction.

Conclusion

Investing in an automated capping machine is an excellent move for beverage can manufacturers. It improves efficiency, quality, and safety while also providing adaptability and future cost savings. As the industry grows and expands, the automated capping machine is a vital asset to accommodate new and changing demands.

Therefore, it is essential to understand the significant benefits of an automated system and consider investing in this crucial piece of equipment. If you want further information about top-quality capping machines, please feel free to contact us at info@ubestcanseamer.com.