Keeping food fresh should be first and foremost crucial to canned food manufacturers. Among the existing preservation methods, vacuum sealing remains the best way for most food products.

No wonder the automatic vacuum can seamer machine is one of the most popular can packaging equipment used in the packaging industry, helping to maximize the shelf life of food products. This article is going to give a brief introduction to the automatic vacuum can seamer machine.

How does the vacuum canning process work?

The vacuum measures the extent to which air is removed from the container to provide a firm closure. The amount of air left in the container after filling is closely related to the vacuum level. While adding only nitrogen during the canning process will not make much difference.

Generally, the automatic vacuum can seamer machine will suck out a normal ratio of air to keep the residual oxygen to less than 3%. Otherwise, there is still enough oxygen in the container to possibly react with the food and affect the quality and nutritional value of the canned food.

Detecting residual oxygen

What are the benefits of a strong vacuum?

- * Reducing the stress on the can and the seams during the heat treatment process.

- * Keeping the can end or jar lid in a concave position to visually indicate the condition of the container.

- * Reducing the amount of oxygen in the container. Food will not be going rancid and will retain quality for a longer period of time.

Why is nitrogen vital for vacuum canning?

The presence of oxygen can introduce moisture, which can reduce the quality of the food. And the most effective way to prevent oxygen damage is to remove and replace the oxygen with an inert gas.

Using nitrogen to purge oxygen from food packaging is a safe practice widely used throughout the food industry. The nitrogen tin can sealing machine has long been used in the food packaging industry to maintain the freshness, integrity, and quality of delivered products.

Another reason nitrogen is often used in food packaging is to provide a pressurized atmosphere that prevents the package from collapsing. Nitrogen can be applied to food packaging types, including bags, bottles, cans, boxes, plastic, or cardboard containers. Therefore, the N2 flushing can sealing machine better protect more delicate foods, such as chips and crackers, from being crushed so easily.

What are the characteristics of the best can packaging equipment for food?

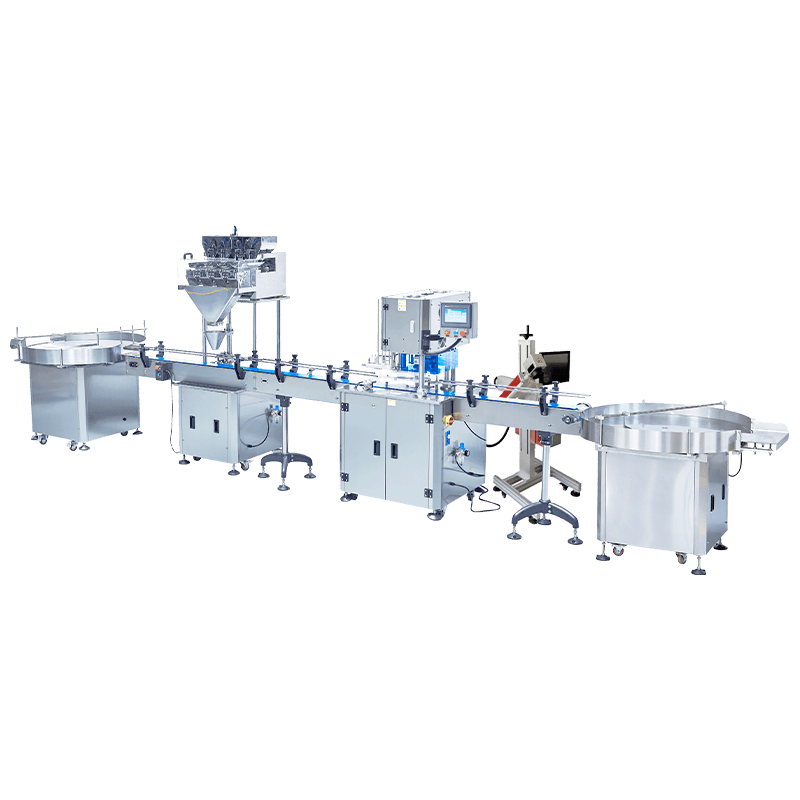

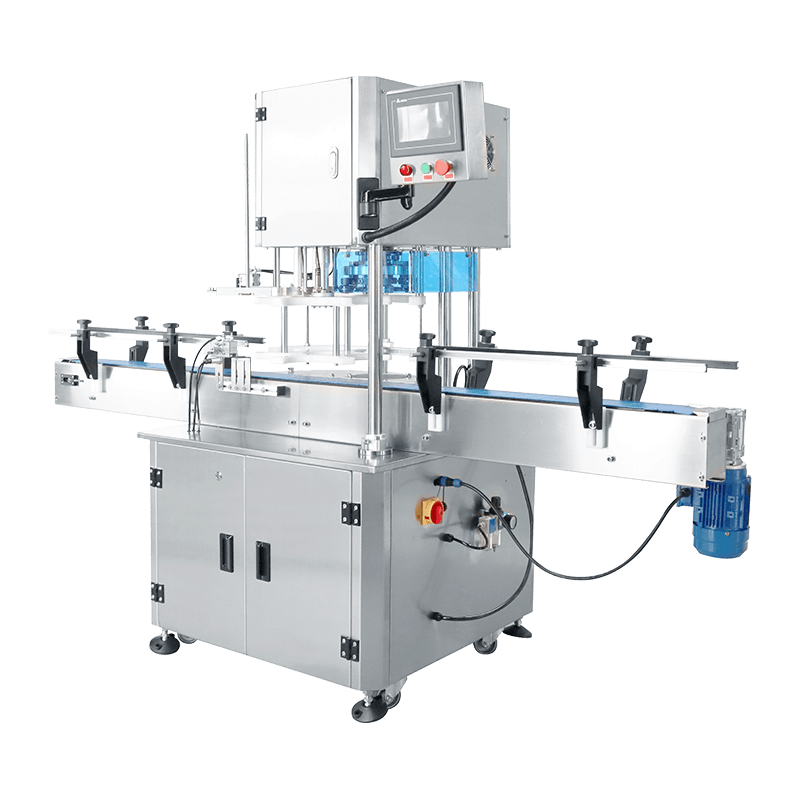

The can packaging equipment for food should combine the advantages of both the automatic vacuum can seamer machine and the N2 flushing can sealing machine, as mentioned above. Take the fully automatic vacuum n2 flushing can seaming machine from Ubest as an example.

Step 1: Cans to be seamed are automatically fed through an integrated conveyor and advanced to the sealing station.

Step 2: Cans are vacuumed (the residual oxygen content is less than 3%) and then flushed with nitrogen.

Step 3: After the operation is completed, the cans exit to the output tray or the optional output conveyor.

* The desired level of vacuum and gas flush times can be set via the control panel. This fully automatic vacuum N2 flushing can sealing machine also has a multi-flush option for multiple vacuum and flush cycles, if required.

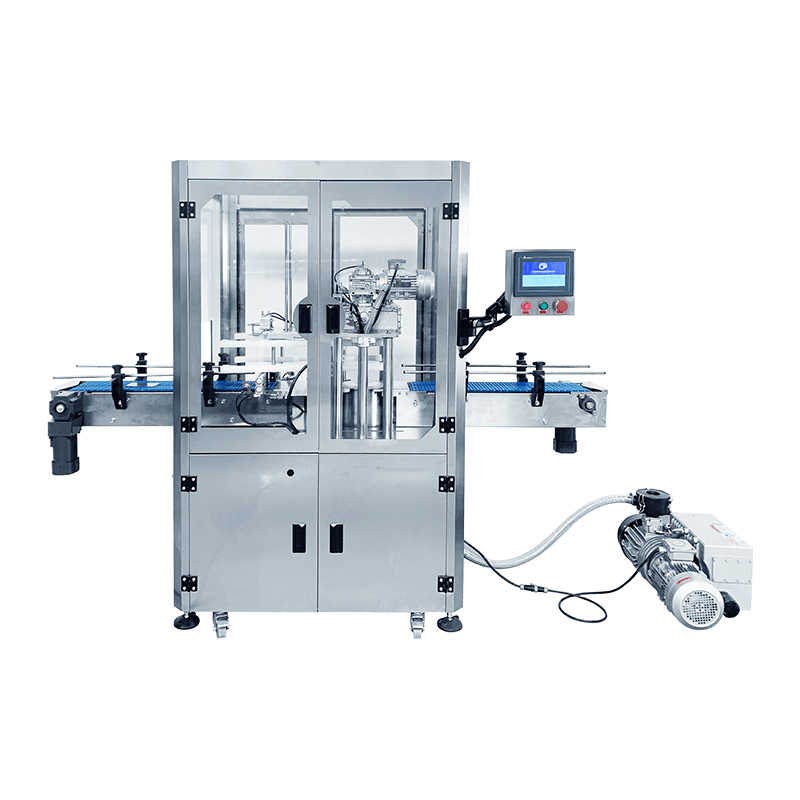

Fully Automatic Vacuum N2 Flushing Can Seaming Machine

In addition, all operations take place continuously without any operator intervention, automating control and operation to increase production efficiency and save labor costs.

This machine possesses the features of the nitrogen tin can sealing machine as well as the automatic vacuum can seamer machine, suitable for all kinds of round opening tinplate cans, plastic cans, etc. Effectively prolong the product storage period, perfect for food, beverage, pharmaceutical and other industries.

Ubest is one of the leading can seaming machine manufacturers and suppliers in China. You can find the best can packaging equipment here, including the automatic vacuum can seamer machine, N2 flushing can sealing machine, and nitrogen tin can sealing machine you may looking for! Please feel free to contact us at info@ubestcanseamer.com for more details!