If you are in the beer manufacturing or supplying business, you know the importance of packaging. The way your beer looks and feels in a can can make all the difference in attracting customers. That’s why investing in the right beer can filler and seamer is essential. In this blog post, we will dive into everything you need to know about beer can fillers and seamers, from their purpose to key features and benefits.

Purpose of Beer Can Filler and Seamer

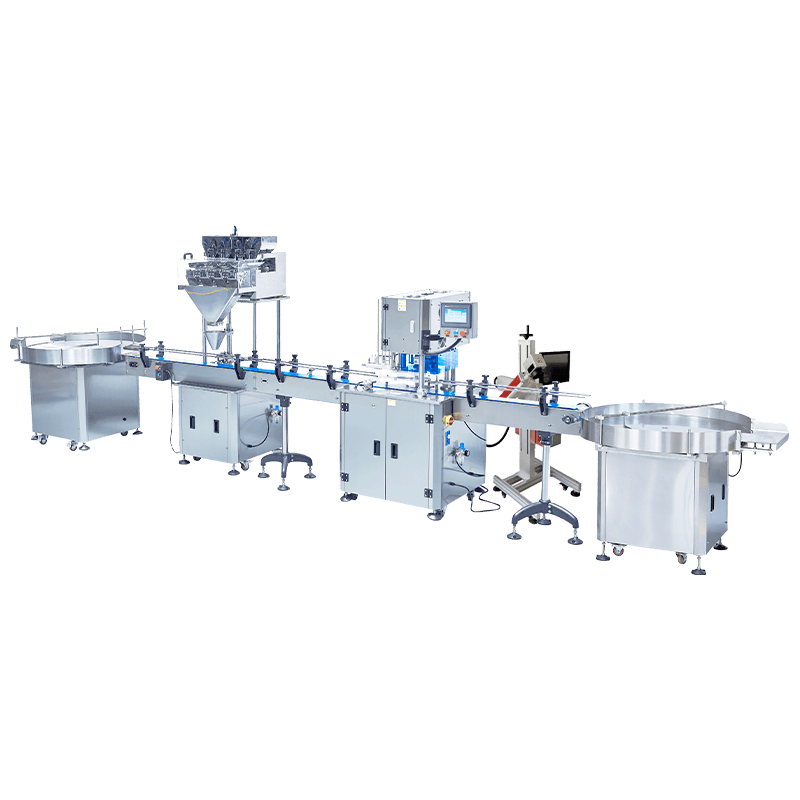

The primary purpose of a beer can filler and seamer is to fill beer into cans and seal them. The filler requires precise measurement and control to ensure consistency in taste, carbonation, and quality. The seamer must efficiently seal the cans, preventing any air from getting inside and keeping the beer fresh for an extended period. The process of can filling and seaming involves various stages, and the right equipment can make it all smoother.

Key Features of Beer Can Filler and Seamer

When selecting a beer can filler and seamer, it is crucial to look for certain features that ensure optimal performance and durability. Here are some of the key features to consider.

Capacity: Choose a machine that meets your production needs, considering the size and output requirements of your brewery.

Filling System: Look for an accurate and efficient filling system that ensures consistent carbonation levels and minimizes any waste.

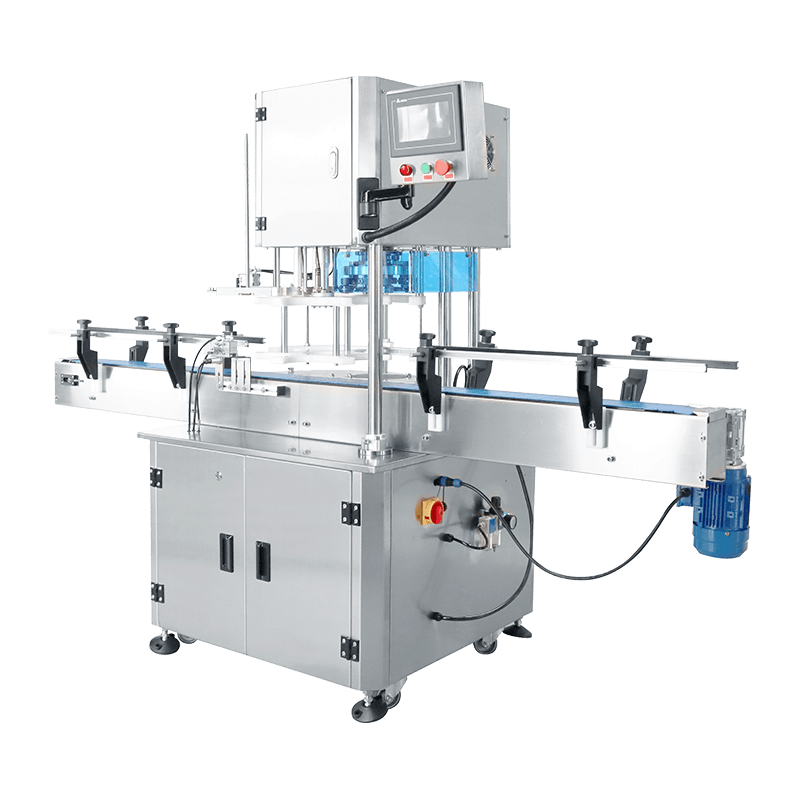

Seaming System: Opt for a seaming system that delivers a secure seal and prevents any leakage or contamination

Canning Speed: You want a machine that can keep up with the pace of your production line without sacrificing quality.

Material and Hygiene: Consider the materials used to build the machine and how easy it is to clean and maintain for optimal hygiene.

Benefits of Beer Can Filler and Seamer

Now that we have covered the purpose and features of beer can fillers and seamers, let’s look at the benefits they offer to beer manufacturers and suppliers.

Improved Efficiency: With an advanced beer can filler and seamer, you can increase your production speed and volume, reducing downtime and labor costs.

Consistency in Quality: The precise measurement and control of the filling system ensure that every can of beer tastes the same, keeping customers coming back for more.

Better Shelf Life: A secure seal provided by the seaming system prevents air from entering the cans, keeping the beer fresher for longer.

Reduced Waste: Accurate filling and efficient can seaming result in less beer waste and lower production costs.

Enhanced Customer Satisfaction: With consistent quality and freshness, customers are more likely to be satisfied with your beer and recommend it to others.

Conclusion

Investing in the right beer can filler and seamer is crucial for any brewery or beer supplier. Look for a machine that offers optimal performance, durability, and hygiene features to ensure consistency and quality in your production line.

The benefits of using an advanced canning machine go beyond increased efficiency and reduced costs, providing better customer satisfaction and loyalty. Don’t compromise on the quality of your beer packaging - choose the best beer can filler and seamer suitable for your business. Please feel free to contact us at info@ubestcanseamer.com for more details!