In today's fast-paced world, efficiency and productivity are key factors for success in any industry. When it comes to the food packaging industry, one of the crucial steps is sealing cans securely and efficiently. This is where food can sealer machines come into play.

These powerful machines not only enhance productivity but also ensure the quality and safety of packaged food products. In this article, we will explore the benefits of using food can sealer machines and how they can help you outrank your competitors in the market.

Improved Efficiency and Speed

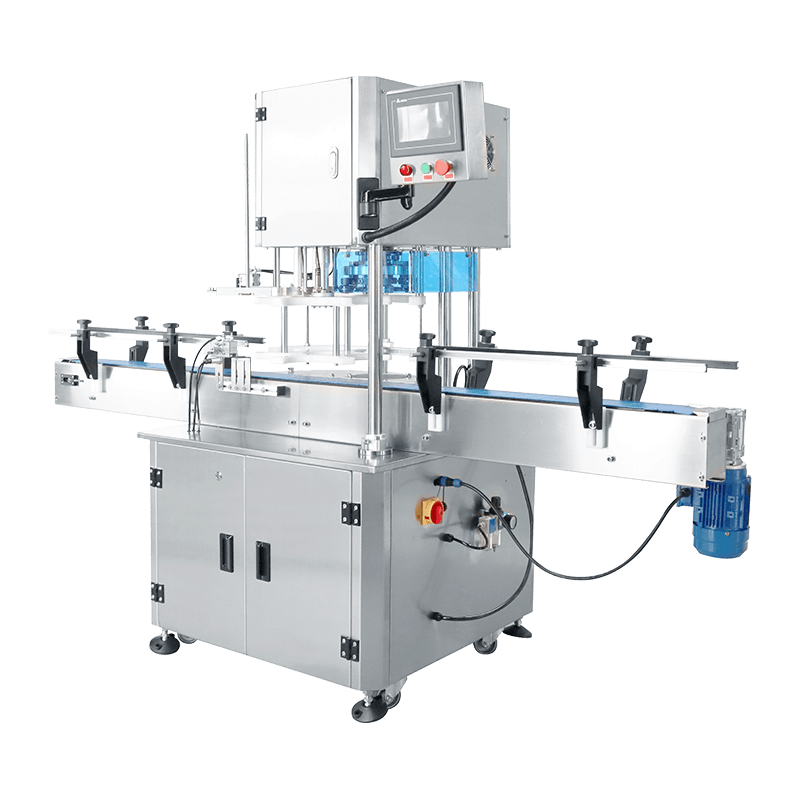

Food can sealer machines are designed to streamline the sealing process, making it faster and more efficient. They can handle a large number of cans in a short period, significantly reducing the time required for manual sealing. With their advanced automation features, they can seal cans consistently and accurately, eliminating human error and increasing overall productivity. By investing in a high-performance can sealer machine, you can expedite your packaging operations and meet the growing demands of your customers.

Ensuring Product Freshness and Quality

Proper sealing plays a crucial role in preserving the freshness and quality of food products. Food can sealer machines provide airtight seals that prevent oxygen and moisture from entering the cans, thereby extending the shelf life of the packaged goods. This is particularly important for perishable food items such as fruits, vegetables, and canned meats. A reliable and high-quality can sealing machine is an excellent option for you to maintain the integrity of your products, ensuring customer satisfaction and reducing the risk of spoilage.

Enhanced Safety and Hygiene Standards

In the food industry, maintaining stringent safety and hygiene standards is of utmost importance. Industrial food can sealer machines are designed with this in mind. They are built from food-grade materials and adhere to strict sanitary regulations. With top-quality food can sealer machine, you can minimize the risk of contamination and ensure that your products meet the highest safety standards. Additionally, can sealer machines reduce the need for manual handling, minimizing the chances of injuries and accidents in the workplace.

Versatility and Customization Options

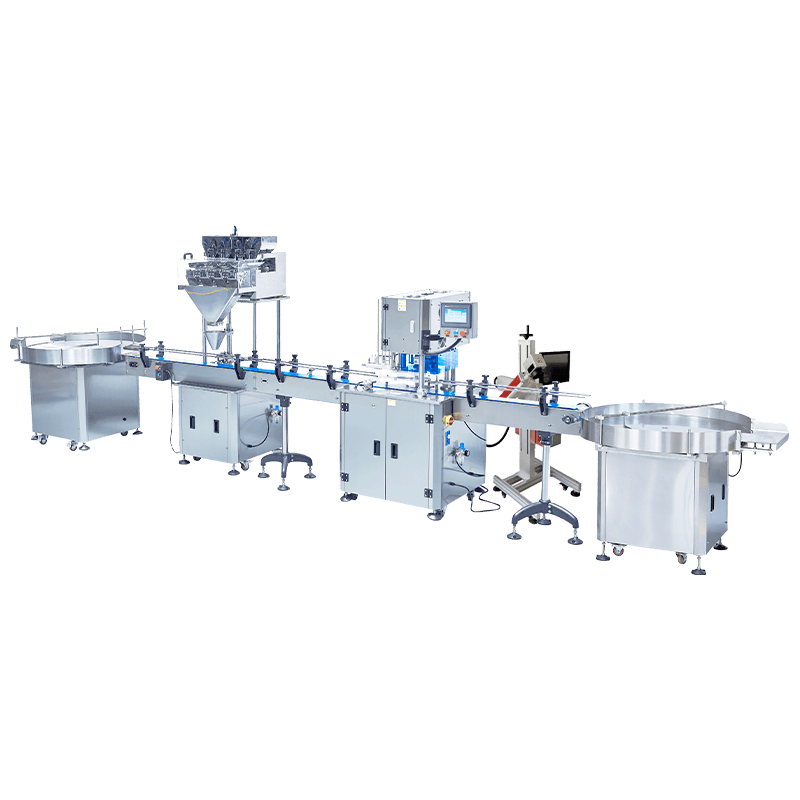

Every food packaging operation has unique requirements, and industrial can sealer machines offer versatility and customization options to meet these needs. Food can sealer machines can handle various can sizes and types, allowing you to package a wide range of products. With adjustable settings, you can modify the sealing process according to your specific packaging requirements. This flexibility enables you to cater to different product lines and expand your offerings, giving you a competitive edge in the market.

Cost-effectiveness and Return on Investment

While the initial investment in an industrial can sealer machine may seem significant, it is important to consider the long-term benefits and return on investment. Food can sealer machines improve productivity, reduce labor costs, and minimize product wastage due to improper sealing. By automating the sealing process, you can optimize your resources and allocate your workforce to other critical tasks. Over time, the cost savings and increased efficiency provided by the can sealer machine will outweigh the initial investment, leading to higher profitability for your business.

Conclusion

Industrial food can sealer machines are a game-changer for the food packaging industry and are indispensable for any food packaging operation. Partner with a professional and experienced food can sealer machine manufacturer and incorporate these state-of-art sealing machines into your production line. You can stay ahead of the competition, meet consumer demands efficiently, and ultimately achieve business success!