In the dynamic landscape of packaging technologies, where innovation constantly reshapes industries, the role of the can filling machine has become paramount. This article delves into more details about it.

Mechanics and Components of Can Filling Machines

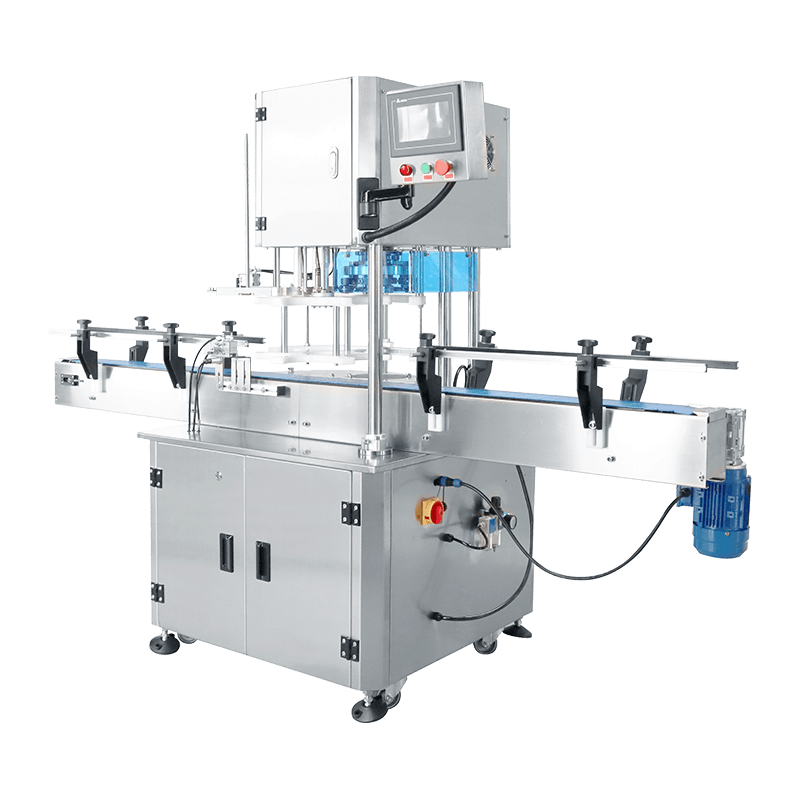

Can filling machines comprise a sophisticated interplay of mechanisms and components that orchestrate the seamless filling and sealing of cans.

- At their core, these machines integrate conveyor systems that transport empty cans through the various stages of the filling process.

- Filling stations equipped with precision nozzles dispense the product into cans with a level of accuracy that ensures consistent fill volumes.

- Subsequently, seaming mechanisms hermetically seal the cans, preserving the contents' freshness.

Types of Can Filling Machines

There are distinct categories of can filling machines, each designed to accommodate different production requirements.

Gravity fillers are renowned for their simplicity and reliability. They operate by utilizing gravity to ensure precise filling, making them ideal for products that don't require pressurized filling.

Pressure fillers, on the other hand, are favored when dealing with carbonated beverages and other products that necessitate controlled pressurized filling to prevent foaming and product loss.

Vacuum fillers distinguish themselves by creating a vacuum within the can before filling. This method minimizes oxygen exposure, a crucial factor for preserving the quality of oxygen-sensitive contents like food products.

Operational Efficiency and Benefits

Precision and Consistency

One of the most commendable attributes of can filling machines is their ability to ensure precise and consistent fill volumes. This not only eliminates product wastage but also maintains the integrity of brand reputation through uniform product quality.

High-Speed Production

Modern industries demand efficiency without compromising quality, and can filling machines deliver exactly that. With their automated processes and high-speed capabilities, these machines can swiftly fill and seal a substantial number of cans, boosting overall production output.

Reduced Contamination Risks

Manual filling processes are fraught with the risk of contamination, which can adversely affect consumer health and brand credibility. Can filling machines, through their automated and enclosed systems, drastically reduce the chances of contamination, adhering to the strictest hygiene standards.

Customization and Adaptability

Variable Can Sizes and Materials

The versatility of can filling machines shines through their ability to accommodate a range of can sizes and materials. This adaptability empowers manufacturers to diversify their product offerings without extensive machinery reconfiguration.

Adaptive Filling Parameters

Different products demand distinct filling parameters. Can filling machines can be fine-tuned to adjust filling speeds, nozzle sizes, and other variables, ensuring optimal filling for a diverse array of products.

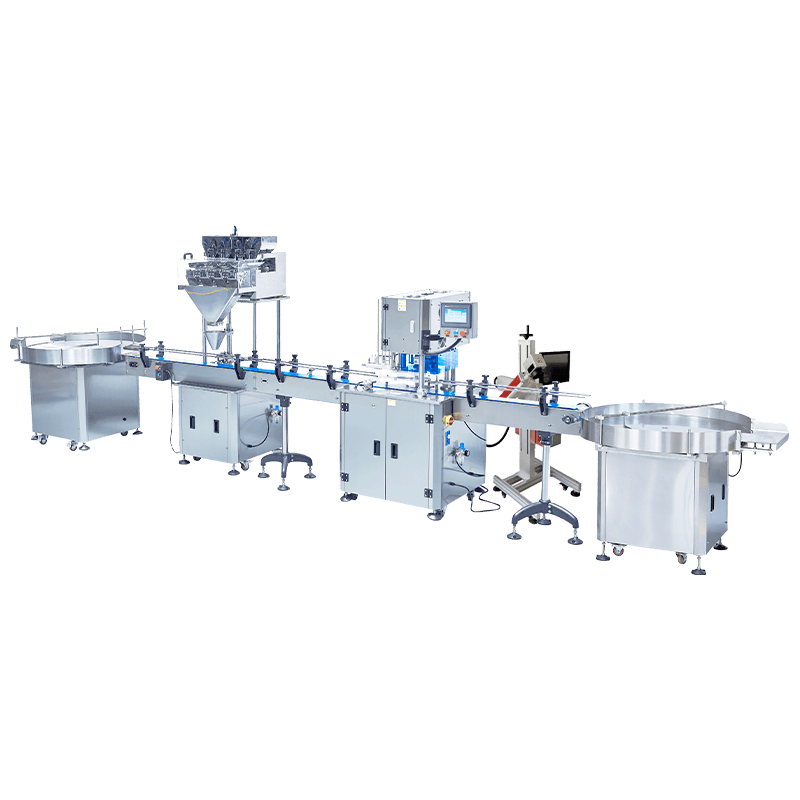

Integration with Production Lines

In the interconnected realm of modern production, can filling machines play a pivotal role by seamlessly integrating with other production line components, such as labeling and packaging units. This synergy streamlines the entire packaging process, enhancing overall efficiency.

Conclusion

The can filling machine stands as a testament to the innovation driving the packaging industry forward. As industries continue to evolve, it is poised to adapt and revolutionize packaging in ways that continue to amaze and improve. If you are looking for more top-quality can filling and sealing machines, please feel free to contact us at info@ubestcanseamer.com.