In today's fast-paced world, where convenience and freshness are paramount, businesses and individuals alike seek innovative solutions to preserve and package food effectively. The can lid sealing machine has emerged as a game-changer in the packaging industry, offering a seamless way to seal cans and maintain product quality.

Can Lid Sealing Machine: A Closer Look

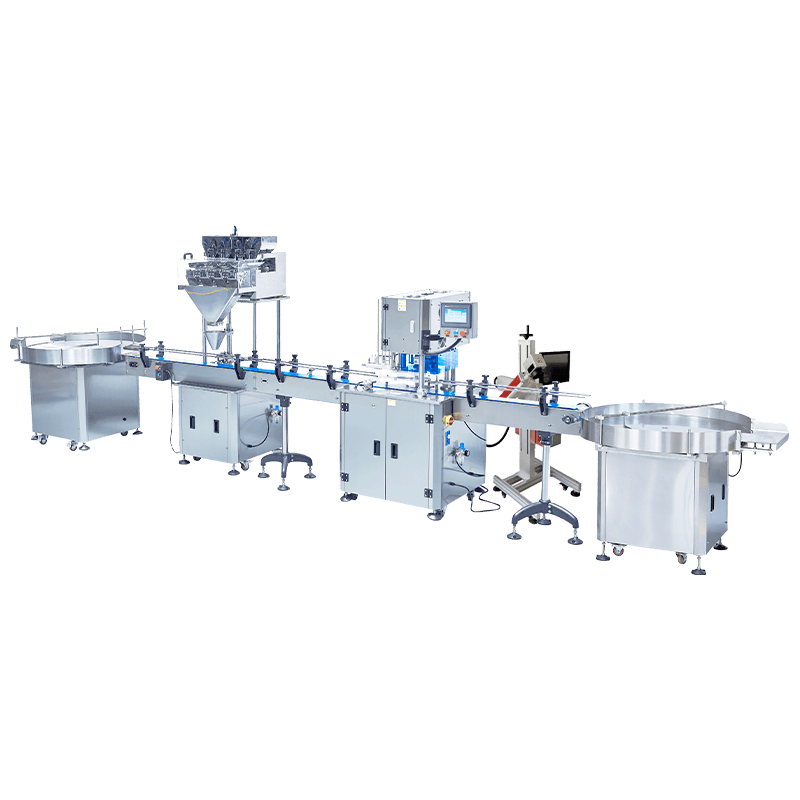

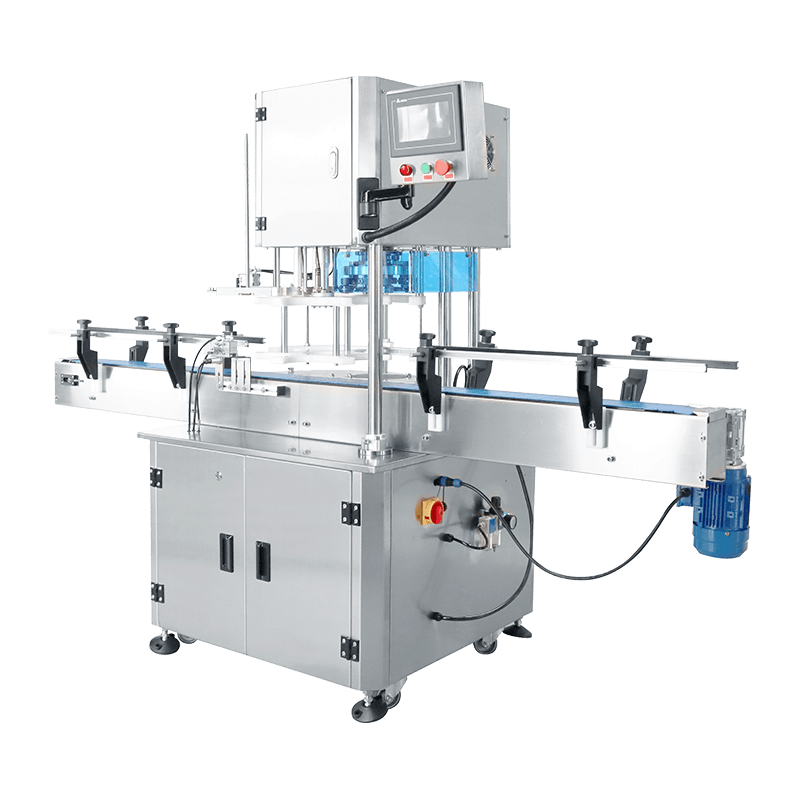

The can lid sealing machine is a mechanical device that automates the process of sealing lids onto cans, creating an airtight seal. This seal prevents the entry of air, moisture, and other external factors that could compromise the product's quality. Utilizing advanced technology, these machines offer a swift and efficient sealing process, making them a valuable asset for manufacturers across industries.

Packaging plays a crucial role in maintaining the quality and shelf life of various products, especially perishable goods. The can lid sealing machine is a technological marvel designed to address this need. With its ability to hermetically seal cans, this machine ensures that the contents remain fresh, free from contaminants, and ready to delight consumers. Let's dive deeper into the various aspects of the can lid sealing machine.

Benefits of Using a Can Lid Sealing Machine

Enhanced Freshness: By creating an airtight seal, the can lid sealing machine preserves the freshness of the product, extending its shelf life and maintaining its flavor and nutritional value.

Convenience: Manual sealing processes can be labor-intensive and time-consuming. The automated operation of the can lid sealing machine streamlines the packaging process, saving time and reducing labor costs.

Product Protection: The sealed cans provide a protective barrier against external elements, ensuring the product remains uncontaminated and safe for consumption.

Improved Efficiency: With its high-speed sealing capabilities, the machine enhances production efficiency, allowing businesses to meet higher demand without compromising on quality.

Customization Options: Can lid sealing machines come with adjustable settings, accommodating various can sizes and lid types, providing versatility in packaging.

Reduced Wastage: The precise sealing mechanism reduces the risk of leaks or spoilage, minimizing product wastage and optimizing resource utilization.

Brand Reputation: Delivering sealed cans conveys a sense of professionalism and reliability, contributing to the positive brand perception among consumers.

Exploring Can Lid Sealing Machine Applications

The can lid sealing machine finds applications in a wide range of industries, revolutionizing the packaging process for various products.

Food and Beverage: From canned fruits and vegetables to beverages, the machine ensures that the contents remain fresh and uncontaminated, delivering a delightful experience to consumers.

Pet Food: Sealing pet food cans effectively maintains the quality of the product, ensuring pets receive the nutrition they need.

Chemical Industry: The machine's airtight sealing capabilities are also utilized in packaging chemicals, preventing leaks, and ensuring safety during transportation and storage.

Pharmaceuticals: Pharmaceuticals require airtight packaging to maintain efficacy. Can lid sealing machines play a crucial role in sealing medication containers securely.

Using the Can Lid Sealing Machine: Step-by-Step Guide

Prepare the Cans: Ensure that the cans and lids are clean and free from debris. Place the product to be packaged inside the cans.

Position the Cans: Place the filled cans onto the machine's conveyor belt, aligning them for the sealing process.

Sealing Process Initiation: Activate the machine using the control panel. The machine will automatically grasp the lids and position them onto the cans.

Sealing Mechanism: The machine employs a combination of pressure and heat to create a hermetic seal between the lid and the can. This process ensures the contents are securely enclosed.

Quality Check: Once the sealing process is complete, a quality check can be performed to ensure all cans are properly sealed.

Packaging and Distribution: The sealed cans are now ready for packaging and distribution. They are well-protected and ready to reach consumers.

Conclusion

In the world of packaging, the can lid sealing machine stands out as a technology that ensures product freshness, convenience, and quality. Its ability to create a secure, airtight seal revolutionizes the way products are packaged and preserved, benefiting various industries and consumers alike. From extending shelf life to minimizing wastage, the can lid sealing machine exemplifies innovation in packaging solutions.