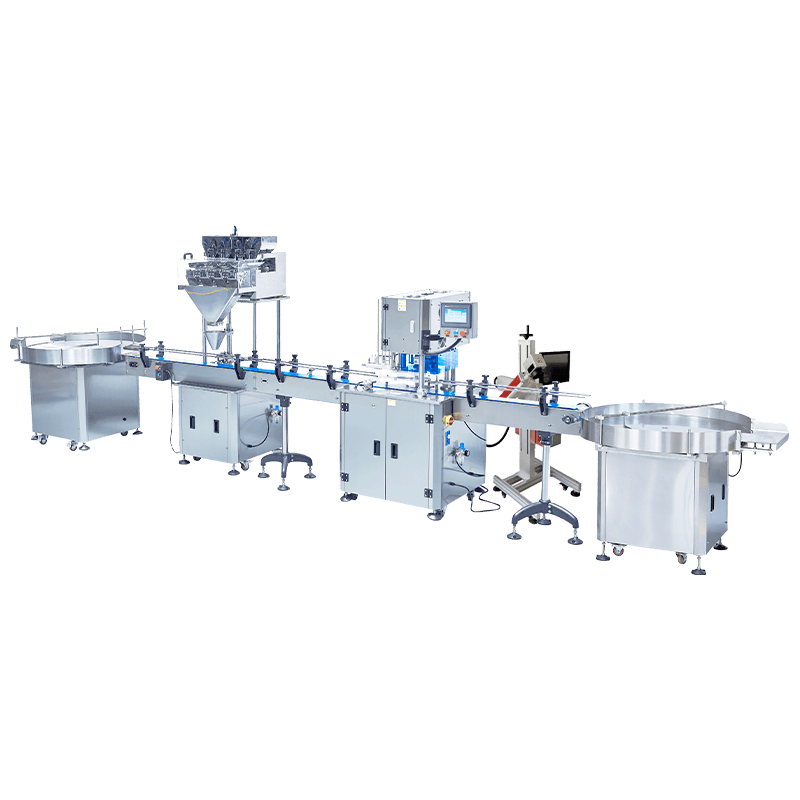

Since the inception of carbonated beverages, the packaging industry has witnessed remarkable transformations. From glass bottles to aluminum cans, the packaging landscape continually adapts to meet consumer demands and technological advancements. Among these innovations, the soda can sealer machine is a critical component in the journey of beverage packaging evolution.

The Role of Soda Can Sealer Machines

In modern beverage production, efficiency, quality, and preservation are paramount. Soda can sealer machines play a pivotal role in achieving these objectives. These machines are responsible for securely sealing aluminum cans, ensuring the freshness and carbonation of the beverage within. Understanding the intricacies of soda can sealer machines unveils the mechanics behind this vital process.

How Soda Can Sealer Machines Work

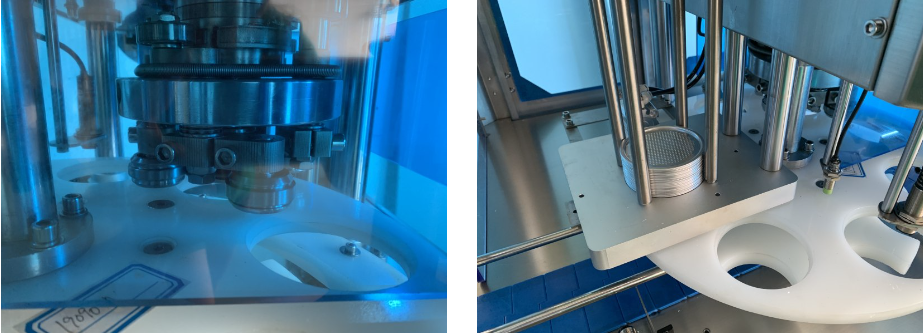

Sealing Mechanism and Components

At the heart of a soda can sealer machine lies a complex assembly of precision components. The lid placement system is designed to position the can lids for sealing accurately. Seaming rollers, equipped with intricate patterns, press the lid onto the can body while creating a hermetic seal. A pressure control mechanism ensures that the optimal amount of force is applied, resulting in consistent and reliable seals.

Double Seaming Sealing Process

The soda can sealing process is a combination of precise movements and calculations. It begins with the careful alignment and placement of the can lid, ensuring that it fits snugly onto the can's rim. The seaming rollers then engage, delicately folding and crimping the lid's edge onto the can.

This double-seaming process guarantees an airtight enclosure that safeguards the carbonation and flavor of the beverage. To maintain the highest standards, quality control measures, such as visual and pressure-based inspections, are implemented to identify any imperfections.

Advantages of Using Soda Can Sealer Machines

Preservation of Freshness and Carbonation

The airtight seal mechanism achieved by soda can sealer machines is paramount in preserving the freshness and carbonation of beverages. By preventing external air from infiltrating the can, these machines extend the shelf life and maintain the sensory experience consumers expect. The protection against contaminants, such as dust and pollutants, further enhances the integrity of the beverage.

Cost-Efficiency and Productivity

In the realm of production efficiency, soda can sealer machines shine. With reduced labor intensity compared to manual sealing methods, these machines contribute to streamlined operations. Their high sealing speeds ensure that cans move through the production line swiftly, optimizing throughput. This combination of factors translates to significant cost savings and enhanced overall productivity.

Customization and Branding

Soda can sealer machines not only serve a functional purpose but also contribute to branding and consumer appeal. The ability to customize can designs and personalize packaging adds a layer of uniqueness to the product. From promotional messages to eye-catching graphics, brands can communicate their identity and captivate consumer attention, ultimately influencing purchasing decisions.

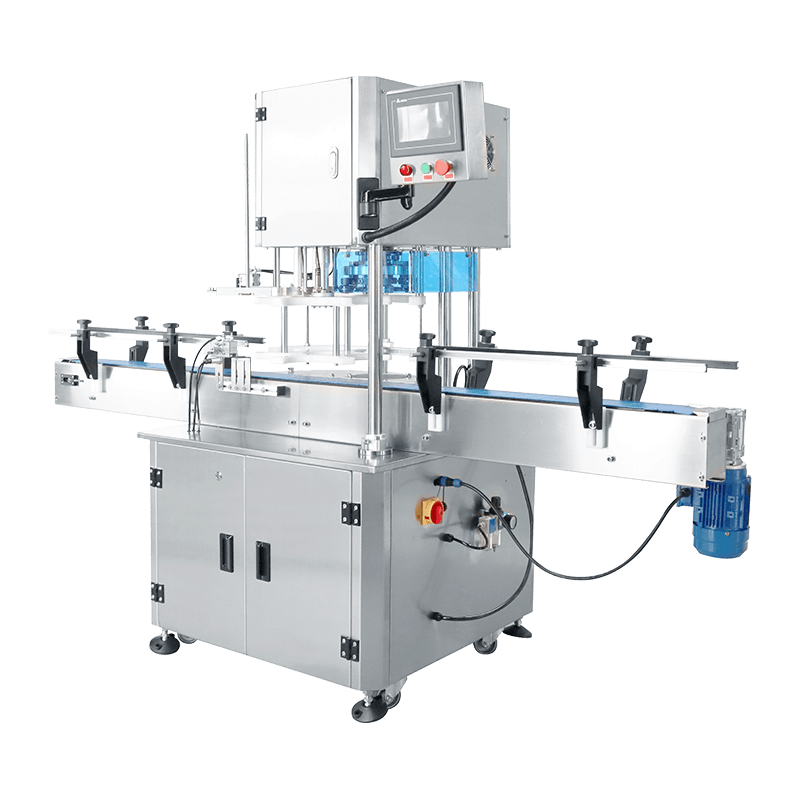

Considerations When Choosing a Soda Can Sealer Machine

Can Size and Compatibility

Selecting the appropriate soda can sealer machine hinges on compatibility with can sizes. Machines are designed to accommodate specific can dimensions, ranging from standard to specialty formats. Manufacturers must carefully evaluate their production needs and product offerings to choose a machine that seamlessly integrates into their operations.

Production Capacity and Throughput

The production capacity of a soda can sealer machine is a critical factor that dictates the rate at which cans are sealed. Matching the machine's throughput with production demands is essential to prevent bottlenecks and ensure a steady flow of finished products.

Sealing Quality and Consistency

Achieving consistent sealing quality is paramount to upholding product integrity. Manufacturers should assess a machine's track record in producing reliable seals, minimizing the risk of leaks or compromised freshness. Consistency in sealing contributes to consumer satisfaction and brand reputation.

Maintenance and Technical Support

Like any complex machinery, soda can sealer machines require regular maintenance to operate optimally. It's crucial to consider the availability of technical support, replacement parts, and servicing options. Adequate maintenance prolongs the lifespan of the machine and ensures uninterrupted production.

Conclusion

In beverage packaging, the soda can sealer machine stands as a testament to innovation and precision engineering. Its intricate mechanisms work harmoniously to ensure the containment of carbonated delights while offering advantages ranging from preservation to branding opportunities. Please feel free to contact info@ubestcanseamer.com for further information about more high-end soda can sealer machines!