In today's dynamic pet food industry, where consumers prioritize the health and well-being of their furry companions, packaging plays a pivotal role in preserving the freshness and nutritional value of pet food. The pet food can seamer is a remarkable piece of machinery that ensures the hermetic sealing of cans, safeguarding the quality of the product within.

About Pet Food Packaging

The history of can seamers traces back to the late 19th century, with manual operations evolving into sophisticated, automated systems. In the pet food industry, the demand for precision and efficiency has driven the development of can seamers that cater to specific product requirements, ensuring optimal sealing and presentation.

Pet food packaging serves as the first point of interaction between a brand and its customers. Beyond aesthetics, it is a functional vessel that must maintain the integrity of the contents. The pet food can seamer, as a critical component of the packaging process, ensures that the contents remain uncontaminated, extending shelf life and upholding nutritional value.

Understanding the Pet Food Can Seamer

Mechanics and Components

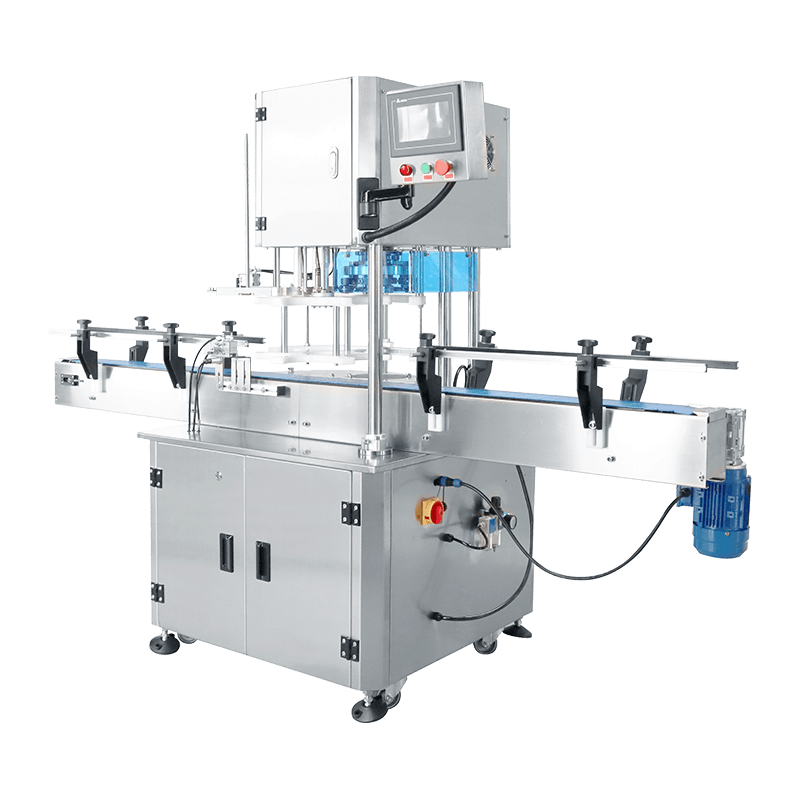

At the heart of a pet food can seamer lies a complex arrangement of mechanical components. The lid placement mechanism, seaming rollers, and body plate work in tandem to create a double seam, which not only securely seals the can but also provides a tamper-evident feature. Each component's precise alignment is essential to achieving a seamless, airtight closure.

Seaming Process: From Lid Placement to Double Seam

The seaming process begins with the accurate placement of the lid atop the filled can. As the can progresses through the seamer, seaming rollers gradually fold and interlock the lid's edge with the can's body, creating a hermetic seal. This double seam not only prevents external contaminants from entering but also maintains the pet food's flavor, texture, and nutritional value.

Importance of Precision in Seaming

Precision is paramount in pet food can seaming. Even the slightest deviation in component alignment or pressure can compromise the seal's integrity, leading to issues such as leakage or compromised freshness. Advanced can seamers employ cutting-edge technology to monitor and adjust the seaming process in real-time, guaranteeing consistent and reliable results.

Advantages of Utilizing a Pet Food Can Seamer

Airtight Seal: Ensuring Freshness and Longevity

The airtight seal created by a pet food can seamer act as a barrier against oxygen, moisture, and other external factors that can degrade the quality of the pet food. This seal preserves the food's taste, aroma, and nutrients, extending its shelf life and maintaining its appeal to discerning pet owners.

Product Safety and Contamination Prevention

In an industry where product safety is paramount, pet food can seamer act as a safeguard against contamination. By preventing entry points for pathogens and foreign particles, the seamer contributes to the overall safety of the product, aligning with regulatory standards and earning consumer trust.

Enhancing Brand Image Through Professional Packaging

Packaging is a reflection of a brand's values and commitment to quality. Utilizing a pet food can seamer to achieve flawless seals enhances the overall appearance and professionalism of the product. This, in turn, contributes to a positive brand image and fosters customer loyalty.

Innovations and Technological Advancements

Automation and Efficiency Improvements

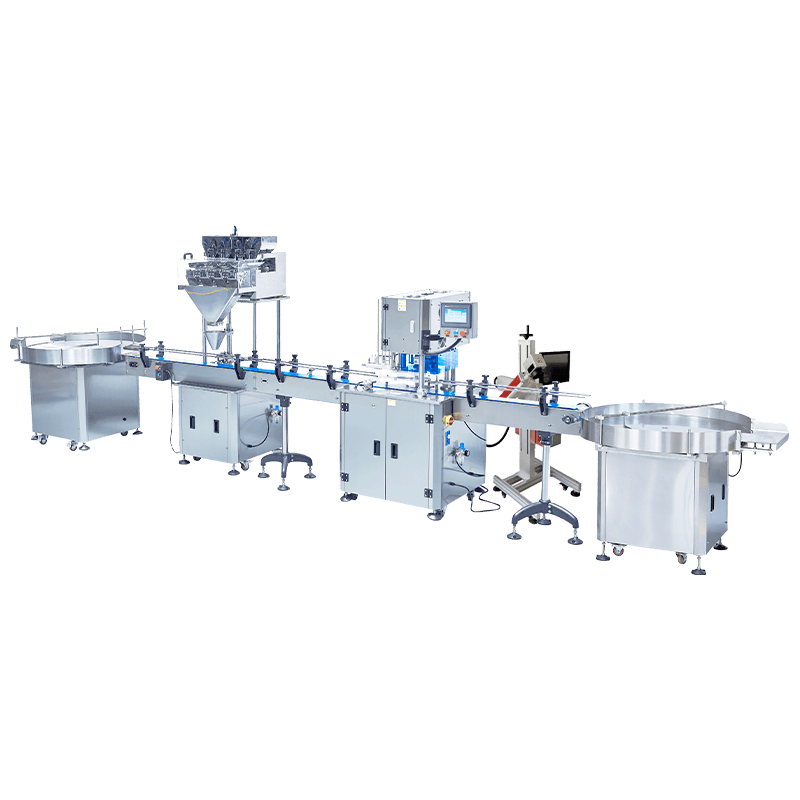

Modern pet food can seamers have embraced automation to streamline operations and improve efficiency. Automated lid placement, seam inspection, and adjustment processes not only reduce human error but also accelerate production, enabling pet food manufacturers to meet market demands effectively.

Seam Inspection Systems: Ensuring Quality Control

To uphold quality standards, seam inspection systems utilize cutting-edge technologies such as machine vision to analyze and verify the integrity of the double seam. Any deviations are promptly detected and addressed, ensuring that only perfectly sealed cans make their way to consumers.

Sustainability Initiatives in Can Seaming

As environmental consciousness grows, the pet food industry has also embraced sustainability in can seaming. Manufacturers are exploring eco-friendly materials and refining processes to minimize waste and energy consumption, aligning with the industry's commitment to responsible practices.

Conclusion

The pet food can seamer delivers both precision engineering and functional aesthetics, making it an indispensable tool in the modern pet food packaging landscape. As technology continues to evolve, so too will the capabilities of the pet food can seamer, ensuring that our furry companions receive the nourishment they deserve in packaging that reflects the industry's dedication to excellence.