For liquid product manufacturers, filling containers, such as jerry cans, can be a time-consuming and labor-intensive process. That’s where jerry can filling machines come in.

These machines offer a range of benefits that can improve the efficiency and accuracy of your packaging process. In this blog, we will explore the benefits of using a jerry can filling machine and how it can positively impact your business.

Increased efficiency and output

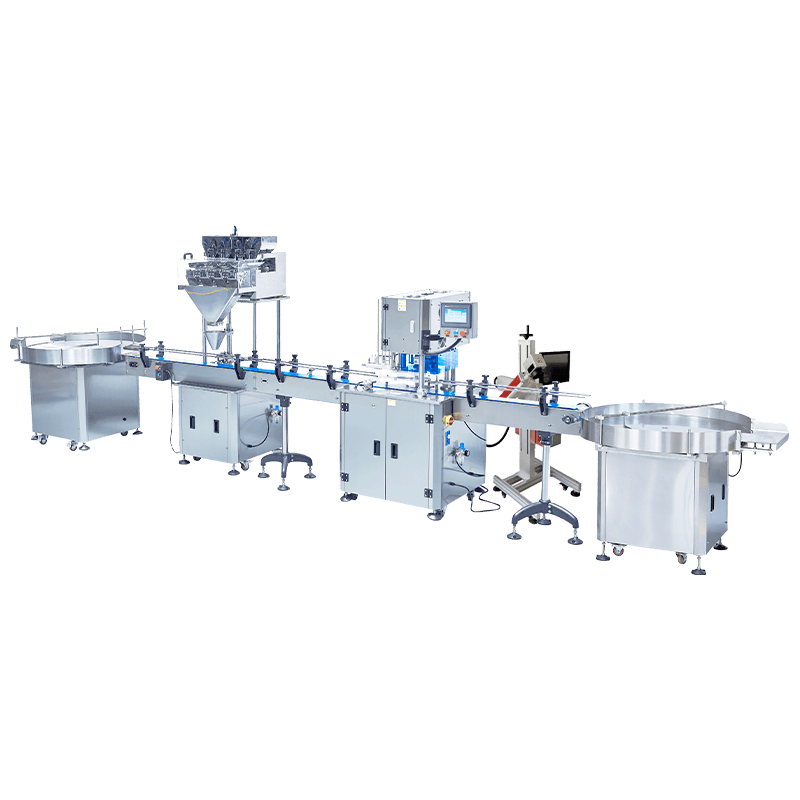

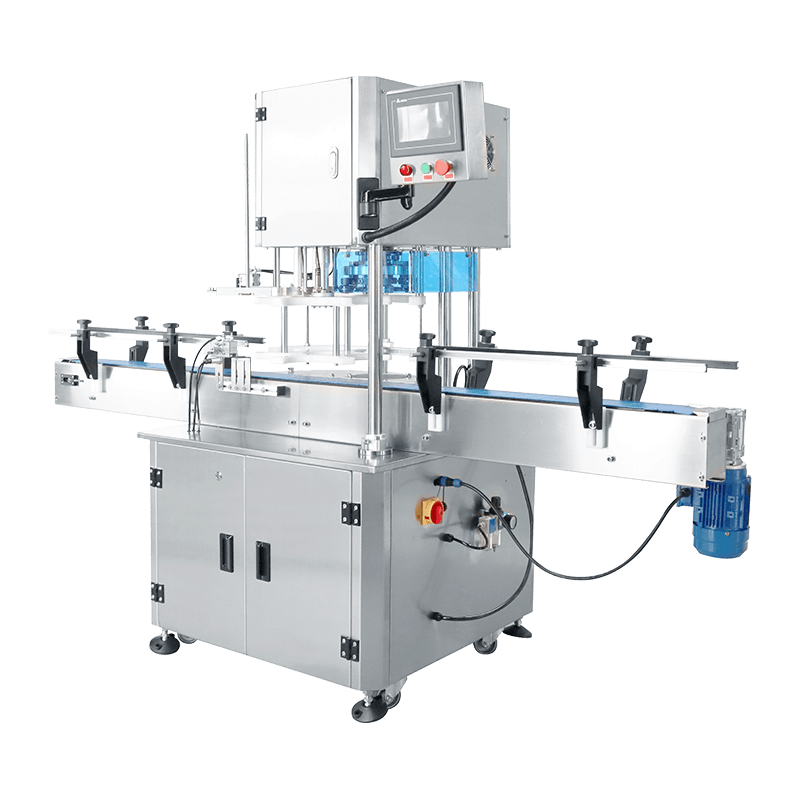

One of the most significant benefits of using a jerry can filling machine is the increase in efficiency and output. These machines are designed to fill containers quickly and accurately, which means you can fill more cans in less time. Additionally, most jerry can filling machines can handle different sizes and shapes of containers, which means you can adapt your production line to meet changing demands.

Improved accuracy and consistency

Hand-filling containers can result in varying amounts of product in each container, leading to inconsistent product quality. With a jerry can filling machine, you can ensure a consistent fill level, resulting in a uniform product and a better customer experience. This consistency also helps to reduce waste and save money on materials.

Reduced labor costs

By automating the filling process with a jerry can filling machine, you can significantly reduce labor costs. Instead of relying on manual labor to fill containers, a jerry can filling machine can handle the task with ease, freeing up your employees to focus on other tasks. This also eliminates the potential for human error, further improving efficiency and accuracy.

Greater flexibility and customization

Many jerry can filling machines come with features that allow for greater flexibility and customization options. For example, some machines offer different filling speeds so that you can adjust production depending on demand. Additionally, some jerry can filling machines can handle different types of liquid products, such as foaming or viscous products, giving you greater flexibility in your production line.

Cost savings in the long run

While jerry can filling machines do require an initial investment, they can save you money in the long run. By increasing efficiency and reducing waste, you can lower manufacturing costs and increase profits. Additionally, automated machines are less likely to break down or require repairs, which saves on maintenance costs and downtime.

Conclusion

A jerry can filling machine is a worthwhile investment for liquid product manufacturers. By increasing efficiency, improving accuracy and consistency, reducing labor costs, providing greater flexibility, and saving money in the long run, a jerry can filling machine can significantly improve your business’s bottom line. Consider investing in a jerry can filling machine to streamline your production line and improve your overall packaging process today!