Can sealers are used to seal the items that need to be stored to keep them fresh, widely used in many industries such as food, beverage, cosmetics, and so on. As you know, the can sealing machine comes in different sizes and types depending on actual usage.

What is the semi automatic can seamer?

Semi auto beverage can seamer only handles one container at a time. While its sealing speed is not that fast, it does deliver some high levels of accuracy compared to the fully automatic can seamer, making them perfect for small productions and hobbyists in the home.

Of course, the semi automatic can seaming machine is also found in high volume production as part of the continuous canning process. After all, it is a very cost-effective alternative to the fully automatic can seamer. Semi automatic can seamer requires the operator to take on additional tasks, such as starting the process, feeding the material into the machine, keeping a close eye on the machine operation, etc.

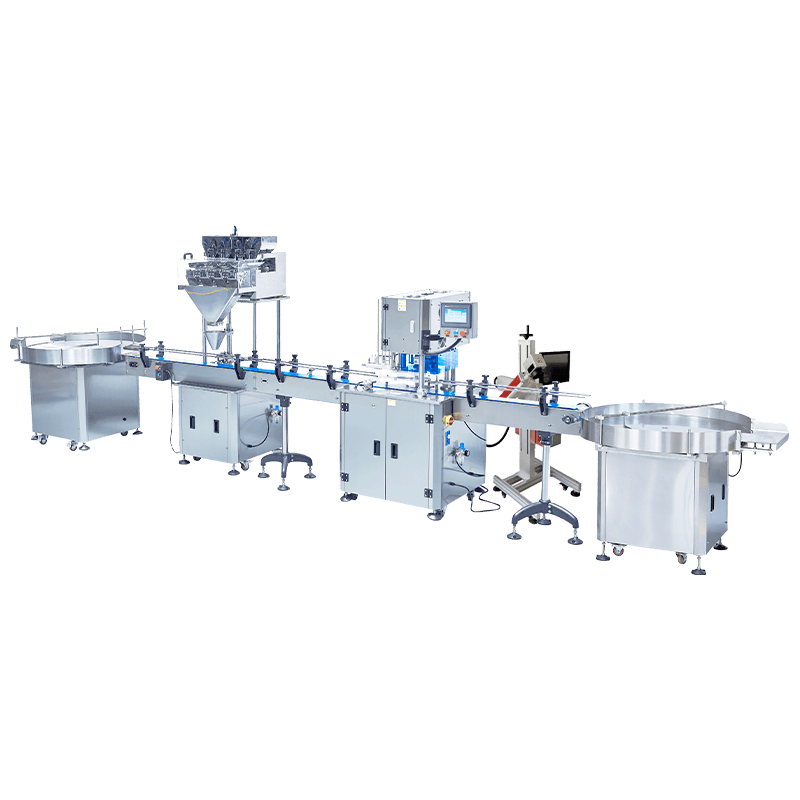

Semi Automatic Can Sealing Machine

Semi Automatic Can Sealing Machine

The rollers of this semi auto beverage can seamer are imported from Taiwan, and the material of the can sealing rollers is made of SKD Japanese special mold steel, which has a long life span of more than 5 million seals on each side.

This semi automatic can seaming machine adopts the double-seamed roller to install symmetrically - one roller completes the crimping, and the other roller completes pressing.

- * The first seaming roller and the knife-edge with hooked groove are deeper than the second hob, rolling the rim during sealing.

- * The second seaming roller with a smoother knife and no hook groove. The seaming roller has the function of blank pressing in the process of sealing.

The simple operating principle can help to reduce the possibility of failure, making the whole sealing process easy to adjust and the force balanced.

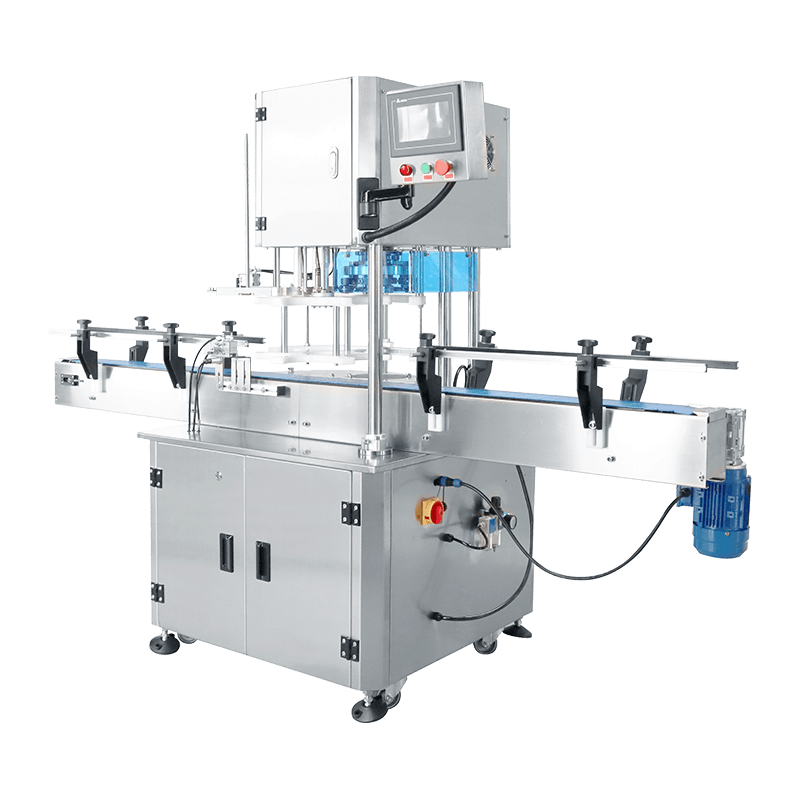

Semi Automatic Pneumatic Can Sealing Machine

Semi Automatic Pneumatic Can Sealing Machine

This semi automatic can seamer tank body does not rotate during the sealing process and has no gear transmission, which is safe and efficient, low noise, and easy to maintain, especially suitable for sealing fragile and liquid products. And this semi automatic can seaming machine allows the operator to seal the can while placing it to improve productivity.

- * Motor - Motor is placed below, providing a low center of gravity, which is easy and safe to move and use.

- * Start button desktop - Manual start button desktop is safer that can avoid safety accidents caused by a foot pedal.

- * Positioning parts - With two positioning parts, it is easy to adjust when handling different can sizes.

- * Available modes - There are 3 modes that are optional - AUTO, JOG, and MAN, which are easy to shift and operate.

- * Cylinder - This semi auto beverage can seamer tray is controlled by a cylinder, and the sealing effect is better, especially for tin cans and paper tubes.

Conclusion

Caning is a widely used packaging method that has been an important part of the manufacturing industry. Therefore, looking for reliable and high-performance semi automatic can seamers is very important. If you're still having trouble choosing which is best for you, check out our website and contact our expert team today for a professional semi automatic can seaming machine solution!