When it comes to modern manufacturing, precision, and efficiency are crucial for success. Packaging may not seem so important, but it plays an essential role in preserving freshness and extending shelf life. Go on and find how can capping machines serve in maintaining product quality.

Understanding the Can Capping Process

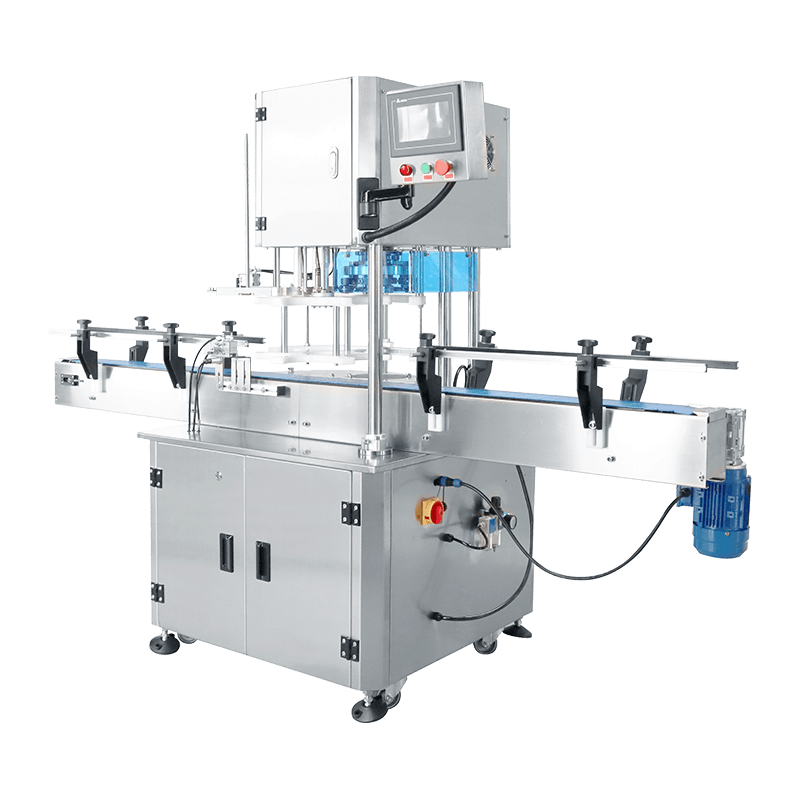

Can capping machines stand as guardians of product integrity are often overlooked. They are tasked with the precise application of caps or closures onto containers, primarily cans. This process ensures a secure seal, protecting the contents from external elements while preventing leaks and spoilage. The silent precision of this task underscores its significance in maintaining the quality of packaged goods.

Behind the scenes, a can capping machine orchestrates a symphony of mechanisms to achieve its task. From cap sorting and placement to torque application, every step is a synchronized effort. Cap feeding systems ensure a steady supply, while torque control imparts just the right amount of force to achieve a tight yet manageable seal. The rhythmic dance of precision ensures consistent results, even in high-speed production environments.

* Matching Functionality with Container: No two products are alike, and neither are their packaging needs. Can capping machines accommodate this diversity by supporting various closure types, from screw caps to press-on lids. The choice of closure depends on factors like product consistency, desired level of tamper resistance, and consumer convenience. This adaptability highlights the machine's role in catering to a wide array of industries, from food and beverages to pharmaceuticals.

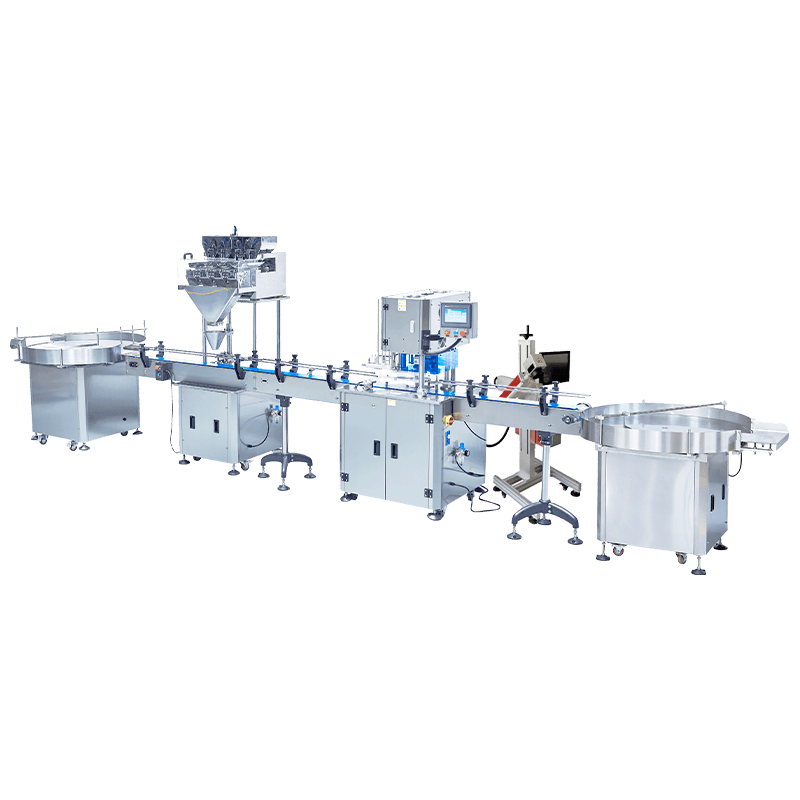

Fully Auto Can Sealing Machine

How Can Capping Machines Function with Precision

Torque Application

The science of torque application lies at the heart of successful capping. Too much torque risks damaging the container, while too little compromises the seal. Can capping machines are equipped with torque sensors and control systems that meticulously measure and apply the optimal amount of force. This delicate balance between torque and container material ensures a reliable seal that withstands the rigors of distribution and storage.

Variable Speed Control

In the realm of manufacturing, adaptability is a prized virtue. Can capping machines offer variable speed control, allowing manufacturers to match production pace with demand. This not only prevents bottlenecks but also maintains the precision of cap application regardless of the production speed. And the result: a seamless, efficient, and responsive production line.

Cap Orientation Systems

Imagine a world where every cap sits askew—a visual and functional nightmare. Cap orientation systems within capping machines ensure caps are properly aligned before application. This optical wizardry involves sensors that detect cap position and adjust the alignment if necessary. The result is a flawless presentation and functional seal, reinforcing the aesthetics and quality of the final product.

Advantages & Benefits

Airtight Seals and Tamper-evident Closures

Can capping machines contribute to consumer confidence by creating airtight seals and tamper-evident closures. Airtight seals preserve freshness and prevent contamination, while tamper-evident features provide visual cues of product integrity. The combined effect of these features not only extends product life but also safeguards consumers' trust in the brand.

Minimizing Errors, Maximizing Output

Even as technology advances, the human touch remains indispensable. Can capping machines embody a harmonious relationship between human operators and automation. Operators oversee setup, maintenance, and troubleshooting, ensuring smooth operations. This symbiosis minimizes errors, maximizes output, and offers a balance between technological precision and human expertise.

Prolonging Lifespan and Consistency

Like any intricate machinery, can capping machines require regular maintenance and calibration. Routine inspections, lubrication, and replacement of worn parts sustain the machine's performance over time. Calibration of torque and alignment systems guarantees consistent results, upholding the quality standards set by the manufacturer.

Conclusion

In the bustling world of modern manufacturing, where quality and efficiency are paramount, the can capping machine stands as a testament to engineering prowess. This unassuming yet essential device ensures that every sealed product carries the promise of freshness and integrity. If you are looking for high-class can capping machines, please feel free to contact info@ubestcanseamer.com for more info!