In the intricate world of food preservation and packaging, the role of a tuna can sealing machine is often overlooked. A seamless, airtight seal on a can of tuna might seem like a mundane detail, but it's a crucial aspect of engineering that plays a critical role in preserving the quality and safety of the product. The evolution of can sealing technology has been a journey marked by ingenuity and precision, driven by the demands of an ever-evolving food industry.

The Significance of Efficient Sealing

In the realm of perishable goods, a hermetic seal isn't just a convenience, and it's a necessity. A properly sealed tuna can prevents the intrusion of contaminants, moisture, and oxygen, thereby safeguarding the product's taste, texture, and nutritional value.

This is particularly vital for seafood, where even the slightest compromise in sealing integrity could lead to rapid spoilage and compromise consumer health. Efficient sealing isn't just about convenience; it's about ensuring the product's integrity from the manufacturer to the consumer's plate.

The Mechanism Behind Tuna Can Sealing Machines

Pneumatic Sealing Systems

Pneumatic sealing systems harness the power of compressed air to create a secure seal between the can body and lid. The process involves controlled pressure exertion on the lid, which is firmly pressed against the can's lip, resulting in a consistent and robust seal. This technology not only ensures airtight closure but also minimizes the risk of damage to the can's structure, preserving the overall product integrity.

Rotary Seaming Process

The advent of the rotary seaming process brought about a revolution in can sealing. This mechanism involves the gradual rotation of the can and lid while precision rollers shape and crimp the metal, creating a seamless bond. The controlled, step-by-step rotation allows for a higher degree of accuracy and repeatability, ensuring each can is perfectly sealed. The rotary seaming process has significantly contributed to the efficiency and quality of can sealing, making it a staple in modern packaging lines.

Vacuum Sealing Advancements

The integration of vacuum sealing technology takes the sealing process to new heights. By removing excess air from the can before sealing, vacuum sealing reduces the oxygen content within the package, slowing down the deterioration of the contents. This process is especially beneficial for tuna and other delicate seafood, as it extends shelf life while preserving the product's original flavor and texture. Vacuum sealing exemplifies the marriage of scientific innovation and culinary preservation.

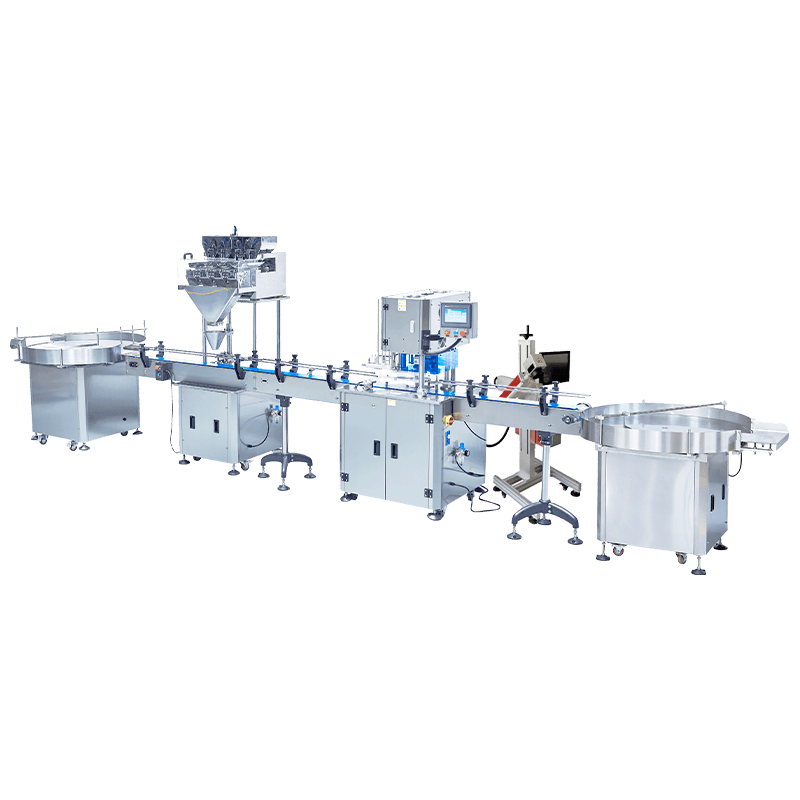

Constant speed can sealing machine

Key Features and Components

Precision Seaming Rollers

At the heart of every tuna can sealing machine are precision seaming rollers. These rollers, meticulously engineered and calibrated, dictate the quality and uniformity of the seal. Their perfectly contoured surfaces ensure consistent pressure distribution during the sealing process, preventing leaks and maintaining the integrity of the seal. This marriage of mechanical finesse and attention to detail is what separates a reliable tuna can sealing machine from a subpar one.

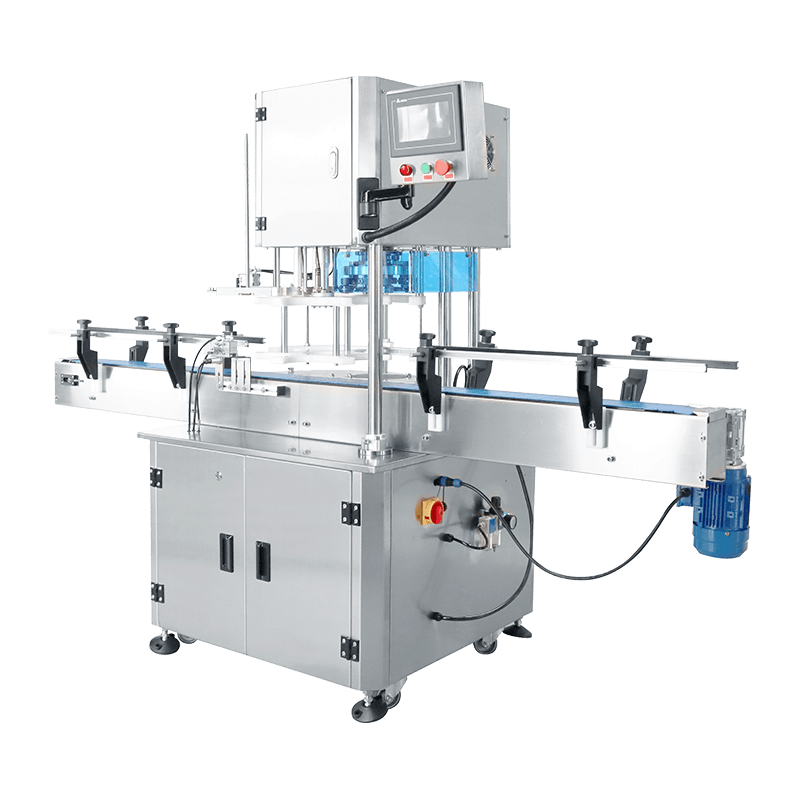

Automated Lid Placement

Automated lid placement systems have transformed the speed and accuracy of can sealing. With this innovation, lids are precisely positioned on the cans, eliminating room for human error and inconsistencies. This level of automation not only enhances efficiency but also ensures that each can is sealed with the same level of precision, meeting the stringent quality standards demanded by modern food production.

Integrated Quality Control Systems

The incorporation of quality control systems within tuna can sealing machines is a testament to the industry's commitment to excellence. These systems monitor every step of the sealing process, from lid placement to the final seal integrity. Any deviations or anomalies are swiftly detected and rectified, guaranteeing that only cans with impeccable seals make their way to the consumer. This integration of technology and quality assurance underlines the dedication to providing the highest caliber of packaged goods.

Benefits and Impact on Industry

Enhanced Product Freshness and Shelf Life

The impact of a well-sealed tuna can transcends the manufacturing floor. By preserving the product's freshness and extending its shelf life, tuna can sealing machines contribute to reduced food waste and enhanced consumer satisfaction. Tuna that retains its original flavor, texture, and nutritional value even after months on the shelf speaks to the power of effective sealing technology.

Streamlined Production Efficiency

In an industry where speed and efficiency are paramount, tuna can sealing machines shine. The automation of the sealing process streamlines production, reducing the need for manual labor and optimizing throughput. This not only accelerates the manufacturing cycle but also lowers operational costs and allows manufacturers to meet market demands with greater agility.

Reduction in Manual Labor

Gone are the days of labor-intensive can sealing. Tuna can sealing machines have significantly minimized the need for manual intervention in the sealing process. This reduction in physical labor not only improves workplace conditions but also reduces the risk of errors and inconsistencies that can arise from human handling. It's a shift that reflects the evolving landscape of industrial automation and its role in revolutionizing manufacturing practices.

Conclusion

The tuna can sealing machine stands as a perfect combination of precision engineering and culinary preservation. From maintaining freshness to impact on production efficiency, this technology is far from ordinary.

As the food industry continues to evolve, can sealing machines will undoubtedly remain a cornerstone of quality packaging and product integrity. Check out our professional and reliable can sealer machines and find the perfect one to bring your business to the next level!