Today, spices are an excellent way to enhance the flavor, color, and smell of food. And packaging spices well helps keep them fresh for a long time while retaining their natural colors, aromas, and flavors. Therefore, the correct packaging of spices is very important, covering bottles, bags, cans, jars, and so on. So, what is the most popular way to package spices?

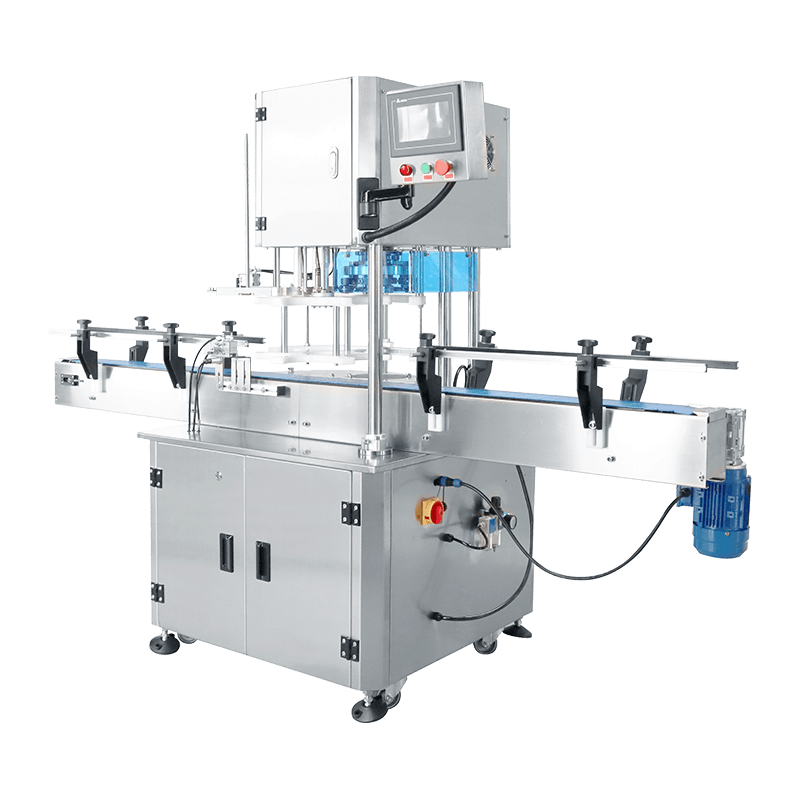

Benefits Of The Tin Can Sealing Machine

As mentioned above, there is a wide range of packaging options for spices. Why does can sealing stand out from several of the most common packaging methods as the most popular one?

Metal cans processed from can sealing machines are usually made of steel, aluminum, tin, and sometimes laminated paper. The automatic can seaming machine is not only efficient but also more affordable for spices, including mustard seeds, turmeric, chili powder, cumin seeds, coriander powder, pepper, etc.

Advantages

- * Most metal cans are relatively lightweight.

- * Some metal cans can be recycled to some extent.

- * Can sealing for spices is easy to use - just open the lid.

- * Cans made from metal can withstand a certain amount of pressure.

- * Metal cans ensure a longer shelf life of spices and reduce the likelihood of spoilage.

- * Cans can be stacked one on top of the other, which is not easy to break and take up less space.

- * Unlike glass jars, cans will not break if dropped from a height, and the spices will not be scattered on the floor.

Note: Please be aware of storage conditions - metal cans may rust in humid conditions.

Different Sealing Designs

Can

Spice cans are available in a variety of sizes and shapes - round, square, rectangular, or any other shape. Therefore, consumers can pick the most suitable package for spices based on their actual needs. For example, small cans are for travel or for portability, while large cans of spices are for everyday use. This is one of the most overlooked issues by spice manufacturers, but it has significant implications for improving user satisfaction.

Jar

Another popular spice packaging design is the wide-mouth jar, which makes it easy for consumers to store and remove solid, non-powdered spices. The spice jar is usually made of glass/plastic and has a slim and transparent body, so it is clear what spices are stored inside. The automatic can sealing machine is also available for glass or plastic, giving a modern touch, and ideal for storing different types of spices.

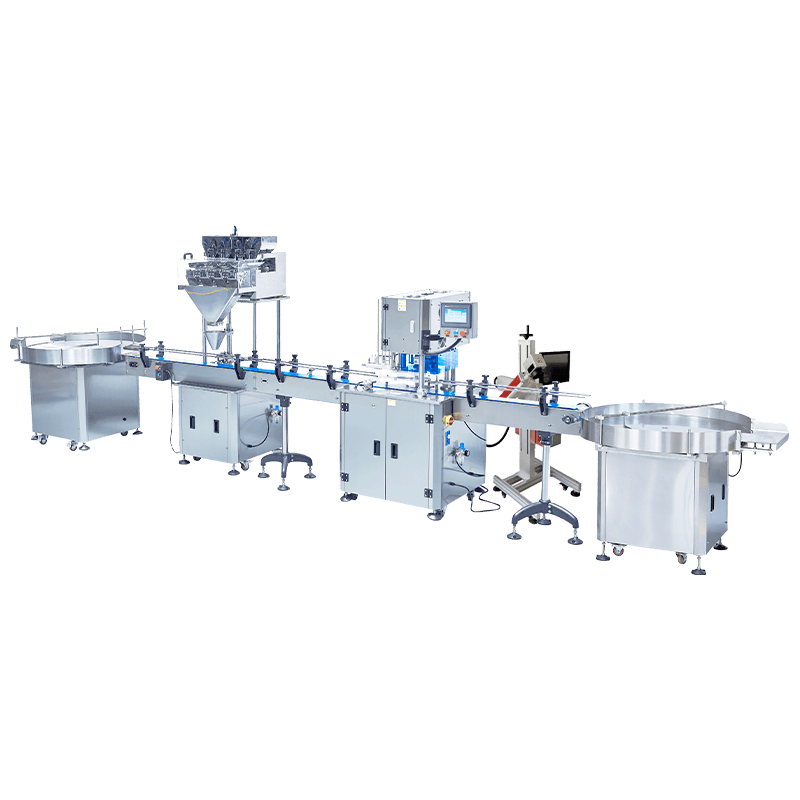

Other Machines in Powder/Granular Production Line

Automatic can filling machine for spice powder: It’s designed for high-quality canning seasonings or other powders with increased precision screw metering and filling. Dust and powder waste will not blow throughout the workshop. Minimize product waste and increase productivity, saving a lot of time and money.

Automatic can filling machine for spice: The main purpose of the spice filling machine is to fill different kinds of non-powdered spices into cans. Small yet fast, user-friendly, versatile, accurate, and non-corrosive. In addition, they can operate quietly and smoothly, are robust, last longer, are easy to maintain, and are safe from leaks.

Can labeling machine: Although hand-labeling is an inexpensive and simple procedure, labeling large quantities of spice cans is not a practical method. Automatic can labeling machine is high-volume machines that can fully automate printing and labeling, increasing production efficiency to save time and cut production costs.

Final Word

All in all, it is vital to choose the top-quality spice automatic can seaming machine to ensure fast production, safe packaging, and overall productivity. Ubest is one of the leading automatic can seaming machine manufacturers & suppliers in China. We not only offer the tin can sealing machine but also the powder/granular production line for various spice packaging needs. Please free feel to contact us for more details!