In today\'s dynamic pet food industry, where consumers prioritize the health and well-being of their furry companions, packaging plays a pivotal role in preserving the freshness and nutritional value of pet food. The pet food can seamer is a remarkable piece of machinery that ensures the hermetic sealing of cans, safeguarding the quality of the product within.

Today, spices are an excellent way to enhance the flavor, color, and smell of food. And packaging spices well helps keep them fresh for a long time while retaining their natural colors, aromas, and flavors. Therefore, the correct packaging of spices is very important, covering bottles, bags, cans, jars, and so on. So, what is the most popular way to package spices?

Since the inception of carbonated beverages, the packaging industry has witnessed remarkable transformations. From glass bottles to aluminum cans, the packaging landscape continually adapts to meet consumer demands and technological advancements. Among these innovations, the soda can sealer machine is a critical component in the journey of beverage packaging evolution.

As we all know, the can sealing machine improves the efficiency of can packaging operations and reduces production costs, which is why it is widely used in various fields to allow enterprises to generate higher profits. However, you need to know how to use a can sealing machine so that you can make the most of it!

In today\'s fast-paced world, where convenience and freshness are paramount, businesses and individuals alike seek innovative solutions to preserve and package food effectively. The can lid sealing machine has emerged as a game-changer in the packaging industry, offering a seamless way to seal cans and maintain product quality.

In the dynamic landscape of packaging technologies, where innovation constantly reshapes industries, the role of the can filling machine has become paramount. This article delves into more details about it.

In fact, many homeowners choose the home use can seamer to improve the storage conditions of certain household items. Proper storage can effectively reduce the possibility that light and air will affect freshness. But with the many types and varying quality of home tin can sealers on the market, how do you find the best one?

In the dynamic world of manufacturing, the need for streamlined processes and precision is paramount. One integral aspect of the packaging industry is the capping of tin cans, ensuring product safety, freshness, and longevity. To excel in this field, a tin can capping machine emerges as a key player, revolutionizing the way manufacturers seal their products.

Can sealers are used to seal the items that need to be stored to keep them fresh, widely used in many industries such as food, beverage, cosmetics, and so on. As you know, the can sealing machine comes in different sizes and types depending on actual usage.

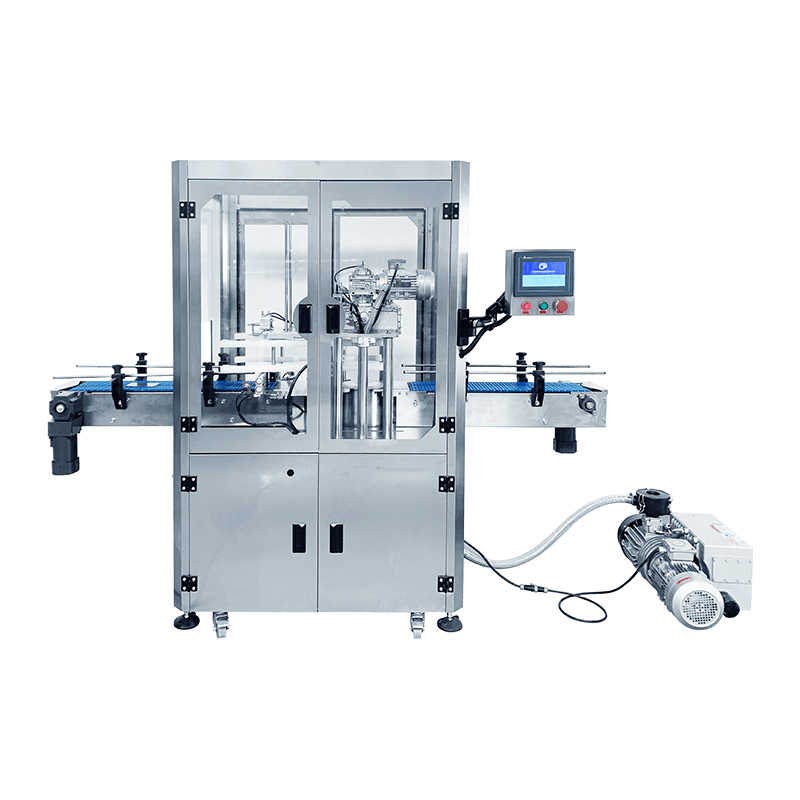

Keeping food fresh should be first and foremost crucial to canned food manufacturers. Among the existing preservation methods, vacuum sealing remains the best way for most food products. No wonder the automatic vacuum can seamer machine is one of the most popular can packaging equipment used in the packaging industry, helping to maximize the shelf life of food products. This article is going to give a brief introduction to the automatic vacuum can seamer machine.

When it comes to modern manufacturing, precision, and efficiency are crucial for success. Packaging may not seem so important, but it plays an essential role in preserving freshness and extending shelf life. Go on and find how can capping machines serve in maintaining product quality.

For liquid product manufacturers, filling containers, such as jerry cans, can be a time-consuming and labor-intensive process. That’s where jerry can filling machines come in. These machines offer a range of benefits that can improve the efficiency and accuracy of your packaging process. In this blog, we will explore the benefits of using a jerry can filling machine and how it can positively impact your business.

Beverage can manufacturers need to ensure that their products are safe, secure, and of high quality. One crucial aspect of this process is the proper sealing of the can. The capping process, however, can be time-consuming and tedious, especially without automation. Thankfully, an automated capping machine can significantly improve the overall efficiency of canning lines. This blog post discusses the benefits of investing in an automated capping machine for beverage can manufacturing.

In the food manufacturing industry, can sealing plays a vital role in preserving the flavor, texture, and quality of canned goods. This is where the round can seaming machine comes in. With its ability to seal cans quickly, efficiently and hygienically, manufacturers can maintain a consistent production rate without compromising on quality. In this blog post, we will provide you with an overview of how the round can seaming machine works, its features, and its benefits.

If you are in the beer manufacturing or supplying business, you know the importance of packaging. The way your beer looks and feels in a can can make all the difference in attracting customers. That’s why investing in the right beer can filler and seamer is essential. In this blog post, we will dive into everything you need to know about beer can fillers and seamers, from their purpose to key features and benefits.